Schedule a Call Back

Institute of Metal Forming and Metal-Forming Machines (IFUM) makes technological advancements in forging

Technical Articles

Technical Articles- Apr 01,18

Related Stories

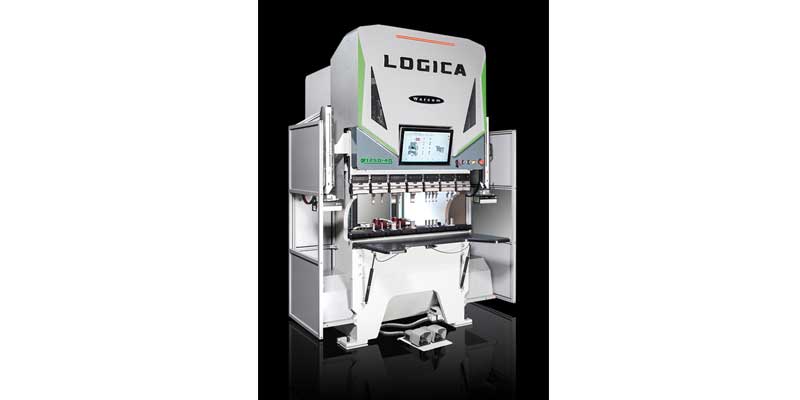

Magal Engineering introduces Logica electric press brake in India

Magal Engineering introduces Logica electric press brake in India

Read more

IMTEX FORMING 2020: The future is here

With more than 500 exhibitors from over 22 countries showcasing their latest products and solutions, IMTEX FORMING 2020 will show the world the capabilities of India’s manufacturing..

Read moreInstitute of Metal Forming and Metal-Forming Machines (IFUM) makes technological advancements in forging

Limited natural resources increase the demand on highly efficient machinery and transportation means. New energy-saving mobility concepts call for design optimisation through downsizing of component..

Read moreRelated Products

Hydraulic Bandsaw Machine, Swing Type

Multicut Machine Tools offers swing type hydraulic bandsaw machines.

Automatic Back Spot Facing Tool

Shenoy Engg Pvt Ltd offers automatic back spot facing tool.

Plas in-line Rotary Pipe Cutters

Arizona Tools Company offers a wide range of in-line rotary pipe cutters for plastic pipe.