Schedule a Call Back

ELGi rolls out EG PM oil-lubricated screw compressors to reduce energy usage

Industry News

Industry News- May 23,24

Related Stories

How to build India’s global manufacturing capabilities?

The Indian manufacturing sector stands at a critical juncture, with several opportunities arising from global shifts and local initiatives. But to take advantage of this evolving market, Indian manu..

Read more

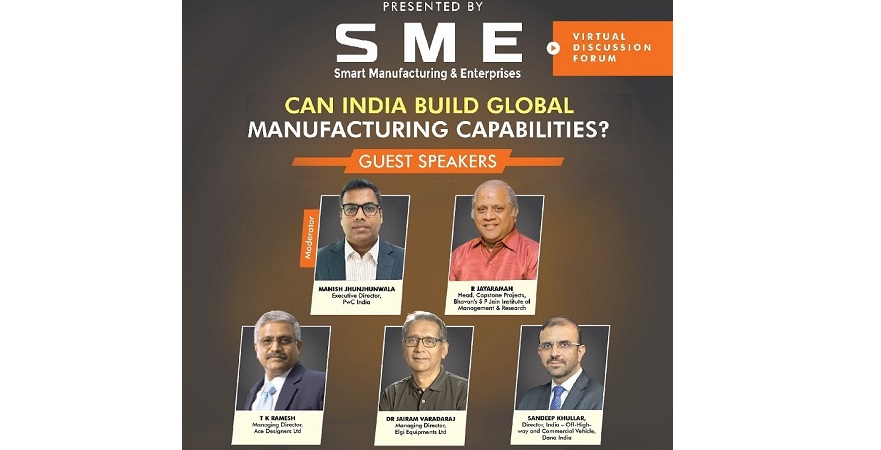

SME to host webinar on how to make India a global manufacturing powerhouse

The virtual panel discussion, "Can India Build Global Manufacturing Capabilities?", will be held on June 21, 2024 from 3.30 to 5.00 pm and will present ways to enhance Indian manufacturers competiti..

Read more

ELGi rolls out EG PM oil-lubricated screw compressors to reduce energy usage

The system's direct coupling ensures optimised motor and airend speeds, facilitating synchronous operation and peak performance, especially beneficial in variable speed applications.

Read more