Schedule a Call Back

Why Cleantech-driven Recycling is the key for India to Lead Global Manufacturing

Articles

Articles- Jan 21,26

- Cleantech-driven recycling can reduce India’s near-80 per cent import dependence on critical cleantech components while strengthening supply chain resilience.

- Recycling-led circular manufacturing offers a cost, sustainability and export advantage under the National Manufacturing Mission.

- Scaling impact requires dedicated finance, higher R&D investment, and over 150 recycling and recovery hubs by 2030.

- Workforce skilling and domestic procurement policies are essential to position India as a global hub for sustainable manufacturing.

Related Stories

Why Cleantech-driven Recycling is the key for India to Lead Global Manufacturing

Cleantech-driven recycling can cut import dependence, strengthen supply chains, create jobs, and position India as a global leader in sustainable and circular manufacturing, comments Akhilesh Bagari..

Read more

CEAT Partners CleanMax for 59 MW Hybrid Wind–Solar Power Project

CEAT has partnered with CleanMax to source ~59 MW of hybrid wind–solar power for its Halol and Kanchipuram plants, boosting clean energy use to around 60 per cent and cutting emissions significant..

Read more

Musashi India Expands Bengaluru Plant to Boost Transmission Output

Musashi India has completed Phase 2 of its Bengaluru plant expansion to scale production.

Read moreRelated Products

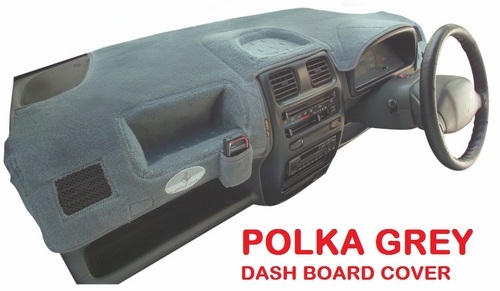

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.