Schedule a Call Back

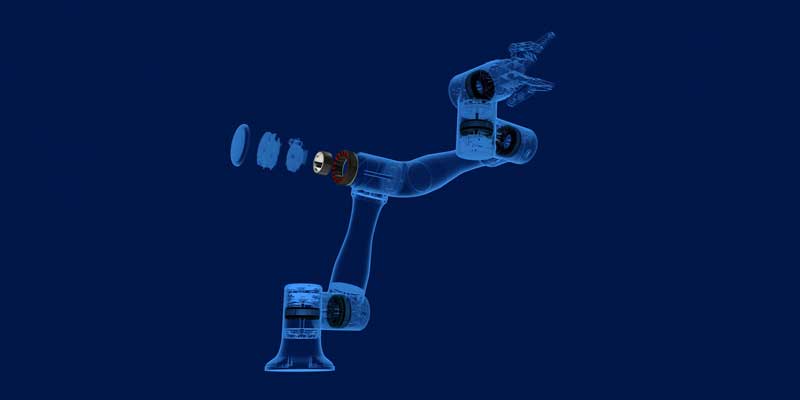

Kollmorgen unveils new robot-ready frameless servo motors

Industry News

Industry News- Apr 28,22

Kollmorgen, a global leader in motion control systems, has introduced new TBM2G series of frameless servo motors, introducing features that simplify the design of collaborative, surgical, aerospace and defense and other robots while delivering optimal performance in a lighter, more compact package. These new motors will complement Kollmorgen’s existing TBM and KBM series of frameless motors.

Resulting from several years of research, testing and customer feedback, the TBM2G series offers high-performance torque in an extremely compact electromagnetics package. These next-generation motors enable robots with lower joint weight, higher load-carrying capacity, improved energy efficiency, lower thermal rise, and faster, smoother movements.

Frameless torque motors typically deliver their best performance at low speeds but suffer at higher speeds. TBM2G motors remove this limitation through advanced windings and materials that deliver industry-leading power, torque and efficiency consistently across a wide speed range.

TBM2G motors also remove the sizing limitation that engineers often face when using off-the-shelf strain wave gearing, also known in the robotics market as harmonic gearing. The new TBM2G series motors are sized for a perfect fit with readily available strain wave systems, eliminating the need for extensive customizations that can increase engineering time and cost while potentially leading to supply and quality issues when robots enter full production.

The TBM2G series is available in seven frame sizes with three stack lengths each—a total of 21 standard motors that can be integrated directly into robotic joints and similar embedded equipment. Typical applications are collaborative robots in the 3–15 kg range, powered at 48 VDC and below. These motors are designed to perform at high speeds without exceeding the 80°C limit typically needed to safeguard humans working in proximity to cobots and to prevent degradation of grease and electronic components. And they’re available with thermal sensor options to meet the requirements of drives and control systems used in the cobot market.

Kollmorgen is highly tooled up to deliver TBM2G motors globally, at any volume, with fast production times, reliable quality and local co-engineering support.

“We’re excited to introduce new servo motors that significantly increase overall performance while reducing size in a wide range of frameless applications. And we’re particularly excited at the possibilities the TBM2G series opens up for robotics. TBM2G motors are a perfect fit for a new generation of high- performance cobots. They are truly robot ready,” said Jeff Czarnecki, Vice President, Global Marketing at Kollmorgen.

Kollmorgen has more than 100 years of motion experience, proven in the industry’s highest-performing, most reliable motors, drives, linear actuators, gearheads, AGV control solutions and automation platforms. Kollmorgen is a brand of Altra Industrial Motion Corp (AIMC), a premier global designer and producer of a wide range of motion control and power transmission solutions. With engineered components and systems that provide the essential control of equipment speed, torque, positioning, and other functions, Altra products can be used in nearly any machine, process or application involving motion.

Related Stories

AI on the edge will transform the shop floor: Sameer Gandhi

In this interview with Rakesh Rao, Sameer Gandhi, MD, OMRON Automation Pvt Ltd, elaborates on trends and opportunities as the manufacturing sector opts for data-led decision-making, quality and safe..

Read more

Taiwan Smart Manufacturing Pavilion spurs India–Taiwan collaborations

Over the course of the exhibition, the Pavilion recorded over 100 industry visitors and engaged with 85 potential buyers, demonstrating a high conversion rate of interest into tangible business lead..

Read more

The human-machine symbiosis: Why Industry 5.0 is the future of manufacturing

Industry 5.0 marks a shift from pure automation to human-machine collaboration. Dijam Panigrahi, Co-founder and COO, GridRaster Inc, explains how technologies like robot rentals, cobots, AR/VR, and ..

Read moreRelated Products

Auto Wheel Hub Bearings

Kasuma Auto Engg Pvt Ltd offers a comprehensive range of Auto Wheel Hub Bearings.

Gear Lever Kits

B S Industry offers a wide range of gear lever kits.

Automotive Gear

Matrix Precision Engineering offering a personalized array of automotive gear.