Schedule a Call Back

JSW Cement's Vijayanagar works set for 12 MTPA expansion and sustainable growth

Industry News

Industry News- Sep 12,23

Related Stories

Premji Invest Infuses Rs 3.0 Billion Equity into JS Auto Cast Foundry

Premji Invest acquires 23 per cent stake in JSA to support capacity expansion and industry consolidation.

Read more

Carraro India opens first authorised service centre in Faridabad

New Faridabad hub marks Carraro India’s aftermarket expansion, with four centres planned nationwide by 2026.

Read more

Resilience in Metal: Forging the Make in India Future in a VUCA World

The article examines how India’s stainless steel sector can turn global volatility, CBAM and supply risks into strategic advantages through sustainability, quality enforcement and digital transfor..

Read moreRelated Products

SLMG beverages launches 100% recycled PET Coca-Cola bottles

SLMG Beverages, a prominent company under the Ladhani Group and a franchise bottler for Coca-Cola in India, unveiled a significant initiative by introducing 100% recycled PET bottles for the renowned Read more

Mineral Water Plant

Richa Environmental Services Pvt Ltd offers a wide range of Mineral Water Plant.

Read more

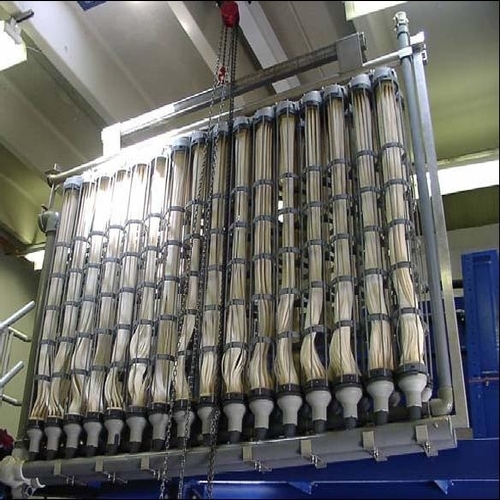

Membrane Bioreactor MBR

They offer high quality Membrane Bioreactor used for industries for their sewage treatment plants , effluent treatment plants.The MBR process involves a suspended growth activated sludge system tha Read more