Schedule a Call Back

GEA to supply one of the largest standalone UHT milk plants in India

Industry News

Industry News- Apr 24,21

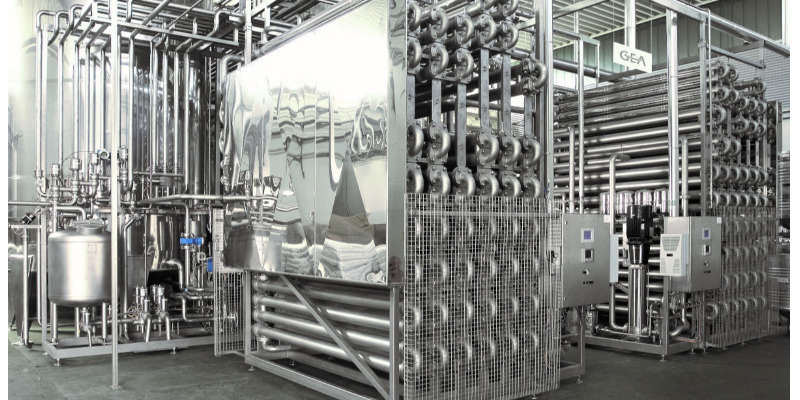

GEA India, industrial technology group specializes in machinery and plants as well as advanced process technology, has won an order to supply a complete ultra-high temperature (UHT) production line for Creamy Foods Ltd. in Uttar Pradesh. Best known for its brand ‘Madhusudan’, Creamy Foods is one of the leading dairy players in the country. This new plant is one of the largest of its kind in India. It opens a new market for UHT technology for GEA in the region.

Creamy Foods is a manufacturer of a wide range of dairy products. It has its processing unit located in Khurja, Uttar Pradesh including plain milk, ghee, paneer, curd, cooking cream, buttermilk, and milk powder. GEA maintains a strong relationship with the company, having supplied a wide range of state-of-the-art dairy processing equipment in the past. GEA’s experience with similar standalone UHT plants across Asia Pacific was a key factor in Creamy Foods’ decision to choose GEA in a highly competitive market.

Menwhile, ultra-high temperature processing, ultra-heat treatment, or ultra-pasteurization is a food processing technology that almost sterilizes liquid food by heating it above 135 °C – the temperature required to kill many bacterial endospores – for 2 to 5 seconds. According to Research and Markets. the market for UHT milk is expected to reach a value of Rs 156 Bn by 2023. Currently, state of Karnataka is the largest market in India, accounting for the majority of the total share.

The scope of work includes supply of a complete UHT line with a proprietary direct steam infusion technology. The line will have a milk processing capacity of 15,000 liters of milk per hour, making it one of the largest standalone UHT milk processing plants in the Indian dairy sector. The complete system, which consists of an indirect UHT combined with a direct infusion high heating module, will be designed and supplied by the GEA Aseptic Competence Center in Ahaus, Germany. The aseptic tank, one of the most critical pieces of equipment, will be delivered from the company’s state-of-the-art manufacturing facility in Vadodara, Gujarat.

Environmental efficiency

This plant is characterised by its hybrid type. While it can process high quality products with the gentle direct infusion technology, it can also switch to the highly efficient indirect mode for processing of standardized quality products. In addition, indirect heating and cooling through special tubular heat exchangers, designed by GEA for a high heat recovery of about 88 per cent over the entire production run, allows cost savings and an environmentally friendly solution for today's ecological needs. It provides a highly effective ratio of volume to heat exchange area to guarantee optimized product quality and high heat recovery with low steam and cooling water consumption.

Amit Agarwal, Managing Director, Creamy Foods, expressed, “We appreciate the innovative and sustainable technologies from GEA and are very satisfied with the performance of dairy processing equipment supplied in the past. For this reason, we are convinced that we have chosen the right partner for our new plant.â€Â

Suket Gohil, Country Managing Director, GEA India, stated, “We are really happy to partner with Creamy Foods once again with our most innovative solution for UHT technology. The dual mode operation makes it a perfect fit for the customer to differentiate their product along with taking care of consumer’ taste preferences. It has the lowest utility consumption, making it more economical and sustainable in the long run,â€Â

The Creamy Foods and GEA signed the contract of supply in February 2020 and the plant is currently under delivery now.

Growing popularity

Around 34 per cent of liquid milk consumption worldwide is UHT with Asia Pacific being one of the top three regions and one where consumption is increasing. Once packed, the product has a shelf life of up to nine months at ambient temperature, making it as practical as it is nutritious, especially where cold chain distribution is difficult to maintain. Among other benefits, the UHT milk due to its longer shelf life does not put added pressure on the cold chain infrastructure and helps to accommodate the space for essential services like drugs and pharmaceuticals and other perishable food.

Related Stories

AI will power the next leap in manufacturing efficiency: Prateek Jain

In this interview with Rakesh Rao, Prateek Jain, COO & Co-Founder, Addverb, elaborates on the changing dynamics of manufacturing sector and role played by automation in driving efficiency.

Read more

Automation and mechanisation will co-exist in Indian manufacturing: Vivek Prasad

In this interview, Vivek Prasad, Executive Director, Avalon Consulting, explains how AI-led automation is elevating manufacturing efficiency and reshaping the future of smart, competitive production..

Read more

Automation is transforming India's manufacturing landscape: Ramesh Bhorania

In this interview, Ramesh Bhorania, Vice President, Robotics & FA Division at Prama Hikvision India, shares how advanced robotics, AI, and digitalisation are transforming India’s smart manufacturi..

Read moreRelated Products

Programmable Controllers - Pcd-33a Series

Pro-Med Instruments (P) Ltd offers a wide range of programmable controllers - PCD-33A Series.

Gasket Graphite Powder

Arihant Packing & Gasket Company offers a wide range of gasket graphite powder.

Asahi Kasei expands 3D printing filament sales in North America

Asahi Kasei, a leading resin and compounding technology provider, has initiated the sales of 3D printing (3DP) filaments in North America through Asahi Kasei Plastics North America (APNA). The soft la Read more