Schedule a Call Back

Zinc Spray Coating On Erw Tube Seam

Zinc Spray Coating On Erw Tube Seam

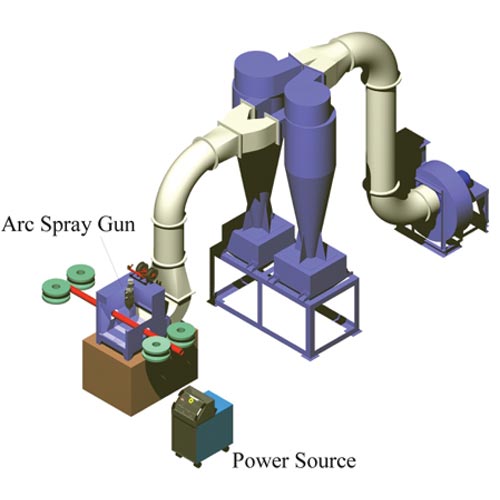

Metallizing Equipment Company Pvt Ltd offers Zinc Spray Coating on ERW Tube Seam. A roll forming machine draws hot or cold rolled steel through successive stations and shapes the material into a tube. Electric resistance welding closes then seam left by the butted edges. Although no filler metal is added that would change the chemical compositions, the welding process applies temperatures high enough to sacrifice some corrosion resistant properties of the base metal. The process may also vaporise aluminium or galvanised coatings previously applied to the rolled steel. The thermal spray process applies coating of zinc to reinstate the corrosion resistance properties of the tubing. Applying the spray while the weld seam is hot assures a metallurgical bond of the sprayed material with the substrate, improves both the deposit efficiency and density of the sprayed material, and allows the coating to blend, thereby helping to hide the weld seam. Arc spray is the most user-friendly and, in terms of operating cost, the least expensive of the thermal or metal spraying processes used for applying metal coatings to base materials. Any electrically conductive material in wire form can be arc sprayed. Wire pulling system by DC Motor, fitted in the gun, which ensures precision wire feed speed. The wires meet at the head of the gun and melt in the electrical arc. The molten mass is atomized and blown on to the substrate with compressed air. The particles cool to ambient temperature and coalesce into a high quality metal coating. The distance from the arc to the tube seam is an important measurement on tube mill installations. Standard arc spray air caps provide conical spray patterns. Straight extensions provide elliptical patterns. A small spray width minimizes over-spray and precisely controls material usage.The company also offers Plasma Spray System for Automotive Components, Thermal Spray Coatings on Industrial Components, Long Term Protection to Steel Mill Rolls, Anti-Wear Coatings on Soft/Hard Metal Bearings, Thermal Spray Coatings for Infrastructure Projects, etc.

Products from Metallizing Equipment Co Private Limited

Plasma Spray System for Automotive Components

Hard Surfacing of Wire Drawing Drums

Thermal Spray Solutions for Pumps

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads