Schedule a Call Back

Laser Cladding

Laser Cladding

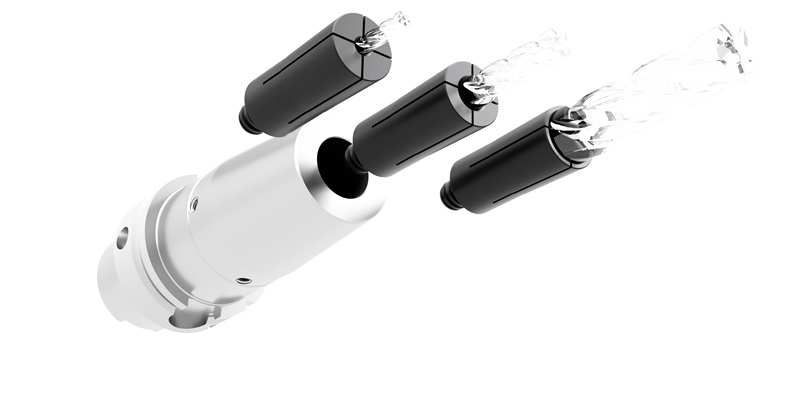

Metallizing Equipment Co Pvt Ltd offers Laser Cladding. Laser cladding falls into the group of processes commonly known as hard-facing. The laser cladding process is a method of applying a fully dense, metallurgically bonded and virtually pure coating, which can be used to increase the wear resistance, corrosion resistance or impact performance of metallic components. In some cases, all three of the properties can be improved. The process utilises a precisely focussed high power laser beam to create a weld pool into which a metallic powder is applied. The powder, which is carried by a stream of inert shielding gas, is blown coaxially through the laser beam. The highly accurate nature of the laser beam allows fully dense cladding with minimal dilution (<5%), yet with a perfect metallurgical bond. Numerous coatings can be applied, the composition of which can be designed to combat the failure mechanisms associated with each component. Fundamentals of laser cladding: typical single layer thickness – 0.2-2.0 mm (multiple layers possible); heat input to part – low to moderate; dilution with substrate material – variable with parameters but can be <5% gives a very pure coating with the desired coating properties; adhesion – full metallurgical bond; density – fully dense (<0.1% porosity); coating materials – WC/Ni alloys, Ni alloys, WC/Co alloys, Stellite 6, Inconel625, FeCrB,