Schedule a Call Back

Coating For Energy Saving In Furnace Operations

Coating For Energy Saving In Furnace Operations

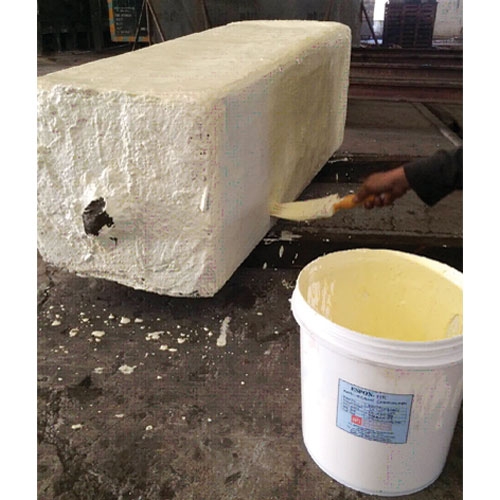

Steel Plant Specialities offers ESPON-RCP Coating for Energy Saving in Furnace Operations in sealed quench, re-heating and heat treatment. Furnace operation plays a major role in both, quality of the heat treated product and cost reduction in heat treatment operations. Uniformity of temperature inside furnace and energy saving are becoming increasingly important due to stringent heat treatment parameters and continuously rising fuel cost. Reduced furnace maintenance downtime and reduced fuel consumption help in increasing productivity and reducing costs. The well-established norms are complete combustion with minimum excess air, operation at the desired temperature, control of furnace draught, utilisation of optimum capacity and recovery of waste heat from furnace flue gases through recuperator.

However, furnace refractory lining must be given due importance in order to increase life and reduce fuel consumption. Ideal furnace refractory must withstand high temperatures and sudden changes in temperatures, conserve heat, have low coefficient of thermal expansion and withstand load and abrasive forces. Alumina bricks used in furnace refractory do not possess all these characteristics and lead to energy loss and frequent furnace maintenance downtime.

A unique protective furnace refractory coating, ESPON-RCP has proven to enable the following benefits:

- Improved thermal shock resistance of the refractory lining

- Improved heat emissivity and uniform heat distribution throughout the furnace

- Prevention of energy leaks through refractory cracks and gaps; increased refractory lining life

- Reduced maintenance downtime

Product & Technology News

ESPON-RCP is useful in furnace operations in the following industries:

Hot rolling, sealed quench and heat treatment, hot forging, iron and steel, sulphuric acid plant, acid regeneration plants, petroleum refining and petrochemical industries.

Products from Steel Plant Specialities LLP

Anti Scale Coating Compound For Hot Forging

Refractory Coating For Furnaces

Accurate Proportioner For Correct Mixing Of Coolants And Lubricants

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads