Schedule a Call Back

Surface Grinder

Surface Grinder

Atul Machine Tools holds expertise in manufacturing, supplying and exporting Surface Grinding Machine. These machines made using quality-assured cast iron that is well tested for such heavy duty usage, ensuring tough construction. Offered machines are made under the guidance of skilled professionals, using modern tools and machines in order to provide highly efficient machine to the patrons. Surface Grinding Machine is real tough in construction and are applauded worldwide by the customers for their operational accuracy. Clients can avail qualitative Grinding Machine from them at economical rates. Compact in structure, these machines are very rigid in construction. Offered machines are vibration free and are available with variable milling speeds along with hydraulic operable table movements. These machines have convenient and perfect angle of wheel dressing mechanism. Valued patrons can avail Hydraulic Grinding Machine from us, ensuring door-step delivery at customers' premises, within stipulated time.

| ID |

| ID |

Manual Surface Grinding Machine 1. Base : The Machine is Built of Heavy duty cast iron with high Grade cast iron bese hand Scraped to fine tolerance to Achieve highest Accuracy. Designe Make Easy Movement of table Slide. By Proviing V-ways and flat ways duly hand Scraped to fine Tolerance to Achieve Highest Accuracy. 2. The Wheel Head: The Grinding Wheel spindle is hardened & Grounded. The Spindle Runs in Precision angular Contact Bearings and driven by flange Mounted Motor though Flexible Couplings, Ensuring through Free Service for a long life. 3. The Mocrofeed System: Vertical Grinding wheel Slide Movement down at right side in the body. The Vertical wheel dial least count in 0.01 mm. and Micro feed least count un 0.002 mm.

Hydraulic Surface Grinding Machine 1.The Structure: The machine is built of heavy duty high grade cast iron. Base is built of hand scraped to achieve fine tolerance & accuracy. Reciprocation table provide V & Flat (guide) ways lining with TURCITE - B for easy movement. 2.The Wheel Head: The Wheel head spindle hardned & ground, runs with precision angular-contact bearings with imported greece to have long trouble free service and driven by flange mounted motor through flexible couplings. 3.The Hydraulic System: Separete Hydraulic power pack is duty fitted with 24 V DC pielot operated Solenoid valve. 4.The Cross Feed: The cross feed is through a lead screw and nut. The automatic cross feed at every reversak if the table is provided through engaged with gear mechanisim and feed controlled by a solid state electronic system. The cross feed is infinitely variable to get desirable accuracy and surface finish. 5.The Micro feed system: Wheel head - slide movement right side in the base. Wheel head feed least count in 0.01 mm and microfeed least count in 0.002 mm.

Products from Atul Machine Tools

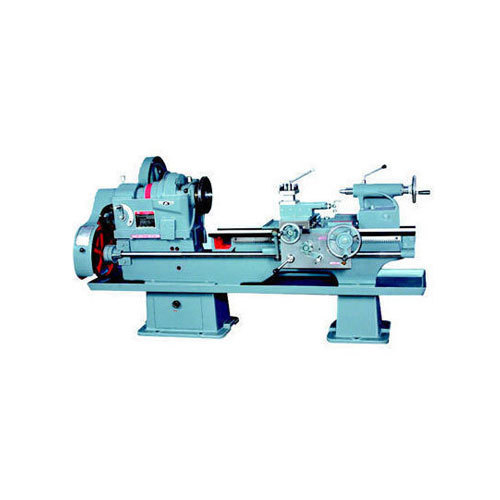

Heavy Duty Precision Lathe Machine

Hydraulic Cylindrical Grinding Machine

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads