Schedule a Call Back

Forging Lubricant

Forging Lubricant

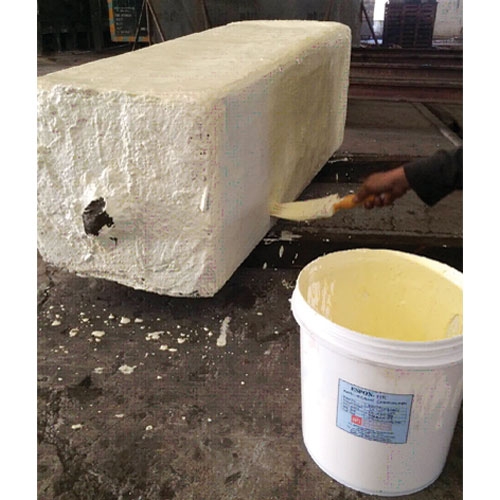

Steel Plant Specialities offers a Forging Lubricant, Espon-GLF3, to increase hot forging die life by up to 100% or more. Hot forging involves plastic forming of heated metals and alloys into desired shapes. In a forge shop, die cost amounts to 10% to 15% of the forging cost. Any increase in the die life automatically increases the profitability of the forge shop. Lubricants play three important roles: reduction in forging load; uniformity in metal flow; and prevention of sticking of forged material to the die. All these factors lead to increased die life. The company manufactures a range of innovative die lubricants as per the needs of the forging industry. Espon-GLF3 is a graphiteless, water soluble lubricant. Benefits of using this lubricant are: improved die life (more than 100% as confirmed by customers); zero pollution without any additional capital equipment; environment protection; and reduced forging cost. Facilities exist to develop customised lubricants for forging steel, aluminium, copper and brass. The same firm has developed special anti-scale compound that prevents component rejections during heat treatment. All these products are found useful by a large number of forge shops in India.

Product & Technology News

Products from Steel Plant Specialities LLP

Anti Scale Coating Compound For Hot Forging

Refractory Coating For Furnaces

Accurate Proportioner For Correct Mixing Of Coolants And Lubricants

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads