Schedule a Call Back

IMTEX FORMING

Technical Articles

Technical Articles- Jan 05,16

An expanded fair for forming technologies

IMTEX FORMING 2016 is a greatly expanded fair and includes all forming technologies predominantly sheet metal as also plastics, ceramics, composites and exotic materials.

From January 21 to 26, Bangalore International Exhibition Centre (BIEC) on Tumkur Road would play host to IMTEX FORMING, the largest event for the Indian Metal Forming Industry. Organised by the Indian Machine Tool Manufacturers’ Association (IMTMA), the apex body of the Indian machine tools industry, this event is claimed to be South and South-East Asia’s leading exhibition showcasing the very latest trends in metal forming machine tools as well as technological re?nements from India and other global players. The mega event attracts visitors from a wide spectrum of manufacturing and ancillary industries starting with key decision and policy makers as well as industry captains who are keen to source latest technologies and manufacturing solutions for their production lines. IMTEX FORMING has come to symbolise as a one-stop forum where customers can experience ‘live’ display of the products enabling them in the decision making process to enhance their manufacturing capabilities.

Forming technology forms an integral part of manufacturing in many industries and has contributed to the development of many new processing technologies, processing methods, machineries, tools and solutions to design and fabricate end products/finished goods. To address the latest trends, developments and research in forming technology, IMTMA is organising a one-day “International Seminar on Forming Technology†on 20th January 2016 in Bangalore coinciding with IMTEX FORMING 2016 exhibition. The seminar will focus on metal forming processes, new materials, tooling and design and emerging technologies and will bring together the fraternity of forming technology on a common platform to discuss related issues.

Ever since the IMTEX series turned an annual event during the last few years, the show alternates between machine cutting machines in odd years and metal forming machines in even years, together making the mega-event a very focussed show for the industry.

IMTEX FORMING 2016 is a greatly expanded fair and includes all forming technologies, predominantly sheet metal, but also plastics, ceramics, composites and exotic materials. The manifestation of this has one ultimate objective: enabling manufacturing excellence through world-class productivity and cost-competitiveness. The mega show as also the concurrent show ToolTech 2016 – International Exhibition of Dies & Moulds, Forming Tools, Machine Accessories, Metrology and CAD/CAM – will layout the very latest machine equipments, processes, tools, accessories, software and raw materials as well as feed stocks required to manufacture formed parts in every engineering application.

Sharing his views on the technology display at IMTEX FORMING 2016, Mr Parakramsinh G Jadeja, the newly elected President of IMTMA said, “High power fibre laser cutting machines is definitely one of the new technologies that would be on display at this IMTEX. Companies will also display servo presses, hydroforming, plasma cutting, profile bending machines, robotic welding and service, and welding technologies. The event will benefit the entire manufacturing sector.†Jadeja is the Chairman & Managing Director of Jyoti CNC Automation Limited, a company he started in 1988 at the age of 20 and has steered its growth since.

Indian Machine Tool Industry

The machine tool industry, along with heavy engineering equipment, is the backbone of the manufacturing sector and hence of strategic importance. It is no coincidence that developed countries across the world – USA, UK, Germany, Italy, Japan, China and Taiwan – are among the leading manufacturers, consumers and exporters of machine tools. Machine tools enable the production of other industrial equipment and machinery – the mother machines – and hence the starting point of almost every metal manufacturing activity. No mass production of metal components, which also means economically viable and with the potential to keep pace with demand, is possible without the use of machine tools. The industry’s prospect mainly depends on the growth of the engineering sector. The user sectors of machine tools are, the automotive, auto ancillaries, railways, defense, agriculture, steel, fertilisers, electricals, electronics, power transmission and telecommunication towers, textile machinery, ball and roller bearings, industrial valves, power-driven pumps, multi-product engineering companies, earth moving machinery, compressors and consumer durables like washing machines, refrigerators, television sets, watches, vacuum cleaners, air conditioners, etc.

The importance was not lost on the government of independent India and Hindustan Machine Tools Ltd (HMT) was conceived in 1949, and incorporated in 1953, with the objective of producing a limited range of machine tools, required for building an industrial edifice for the country. The company has had a string of successful collaborations and technology absorption from leading global companies like Oerlikon and Petermann (Switzerland), Haut Rhin (France) and Gildemeister and Fritz Werner (Germany) in all product groups. The company manufactures a wide range of products: turning machines, grinding machines, gear manufacturing machines, machining centres, other general and special purpose machines (GPMs & SPMs), diecasting machines, plastic moulding machines, various types of presses, CNC systems and precision ballscrews. It served the requirements of a newly independent country quite well and is still going strong six manufacturing units, but has been overshadowed by some of the players in the private sector.

The Indian machine tool industry has around 1000 units in the production of machine tools, accessories/attachments, subsystems and parts. Of these, around 25 in the large scale sector account for 70 per cent of the turnover and the rest are in the SME sector of the industry. Approximately, 75 per cent of the Indian machine tool producers are ISO certified. While the large organised players cater to India’s heavy and medium industries, the small-scale sector meets the demand of ancillary and other units. Many machine tool manufacturers have also obtained CE Marking certification, in keeping with the requirements of the European markets.

According to the 2015 World Machine Tool Output and Consumption Survey by Gardner Business Media published in April, India stands 14th in production and 10th in the consumption of machine tools in the world. The country is set to become a key player in the global machine tools industry and is likely to see substantial high-end machine tool manufacturing, with emphasis on ‘Make in India’ and manufacturing growth, for which the machine tools sector serves as the mother industry.

The machine tool manufacturers in India produce general purpose machinery of international standards (in terms of quality, precision and reliability). However, they lag behind in terms of design and engineering capability so as to be able to undertake very high precision CNC (Computer Numerically Controlled) machines. Due to the gap in technology for special purpose machines and some categories of CNC machines, import of technology is encouraged to bridge this gap. The Indian machine tools sector offers several opportunities for investment. Given the current gap between demand and supply, there is a clear need for adding capacities in this sector. The industry is moving towards increasingly sophisticated CNC machines, driven by demand from key user segments, such as, automobiles and consumer durables, aerospace, etc. Machine tool manufacturers need to develop capabilities to cater to this demand and investments in this area could yield long term benefits. If India aspires to be among the economically prosperous developed nations, it has to raise the share of manufacturing to the GDP which today stands at a mere 15-17%. The examples of successful countries are an indicator where the best example is that of China where manufacturing comprises 35% of the GDP.

There is a strong presence of high tech global machine tool companies in India, presently dominated by German, Italian, Japanese, Korean and Taiwanese companies, many with local partners and manufacturing facilities in the country. Taiwan, which had once captured the imagination of Indian companies with its low cost, low technology products, is today once again poised to make a major splash with its globally popular high tech machines with significant cost advantages. During the Delhi Machine Tools Expo 2015 in September, Mr Lee Guann-Jyh, Director of the Taipei Economic and Cultural Centre in India, Economic Division, had dwelt at length on the increasing contribution of Taiwan’s machine tool industry to the Indian manufacturing segment. Referring to the Indian government’s mission to boost manufacturing to achieve 25 per cent share in overall GDP by the year 2025, he said, “There is a clear-cut synergy between the needs of the Indian manufacturing sector and the special characteristics of the Taiwanese machine tool industry. As the world’s fourth-largest exporter of machine tools and components, the machine tool industry of Taiwan can offer products to a broad range of industries, including aerospace, automobiles, computers, energy, medical equipment as well as precision moulds. The strengths of the Taiwanese machine tool products include excellent quality, reasonable prices, integration and constant innovation, and continuous value-addition. In the future, we truly expect Taiwanese products to help speed up India’s manufacturing energy and make a significant contribution to the ‘Make in India’ initiative.â€Â

Trade between India and Taiwan has been increasing rapidly with Taiwan’s machine tools’ exports to India growing by 11.6 per cent in the first two quarters of 2015. This comes in the wake of the overall Taiwan–India bilateral trade touching USD 2.108 billion in the first five months of 2015. Taiwanese exports to India contributed USD 1.28 billion while imports from India touched USD 828 million. Taiwan now has become increasingly keen on investing in India. At present there are more than 80 Taiwanese companies in India, many of which have successfully expanded their business in the fields of electronics, machinery, food and textiles.

According to a trade report by the Department of Commerce, Ministry of Commerce and Industry of India, Taiwan was among India’s top five machine tool suppliers in 2014. Machining centres, drilling, boring, milling machines, parts and components for metal cutting machine tools are the main types of products imported by India. The production value of Taiwan’s machine tool industry is expected to increase 1.3-1.5 per cent by 2017. In the first six months of 2016, Taiwan exported USD 10.12 billion of machinery, including USD 1.64 billion of machine tools. The momentum of growth over the next four to five years is expected to become better.

Related Stories

Avery Dennison unveils RFID facility in India

The Pune site is set to become a major operational hub supporting industries such as retail, logistics, and healthcare.

Read more

Suzuki, Maruti to establish Osamu Suzuki Centre of Excellence in India

The centre aims to uphold Suzuki’s legacy of promoting efficiency, fairness, and inclusivity in manufacturing.

Read more

Tamil Nadu tops India in electronics exports with $14.65 billion in FY25

This marks a significant jump from $9.56 billion in FY24, reflecting the state’s growing dominance in a sector vital to India’s manufacturing ambitions.

Read moreRelated Products

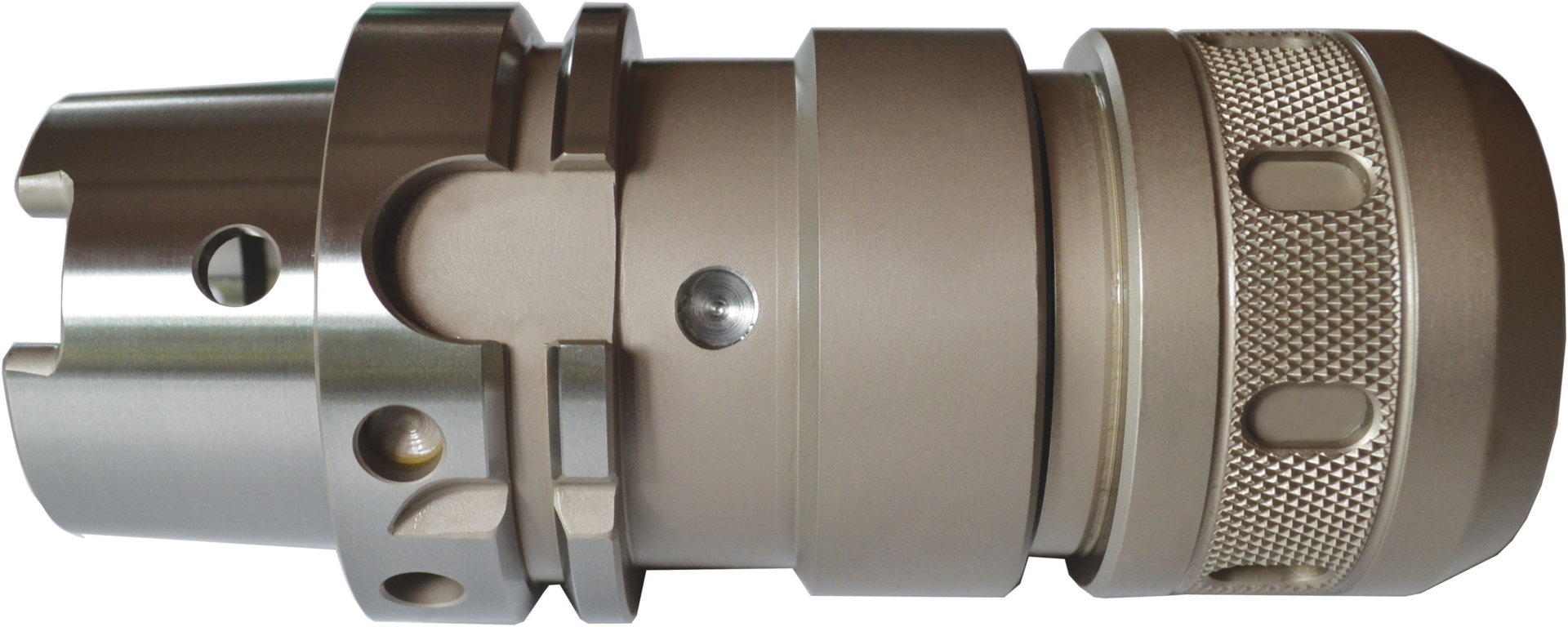

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.