Schedule a Call Back

Global exposure on sheet metal forming processes

Technical Articles

Technical Articles- Nov 30,-1

APM Technologies brought world-class technology of 3D scanning and inspection of sheet metal parts to the door of Indian Industry.

After successful commencement of international workshop on sheet metal forming process at 21 different locations in 14 countries – Germany, Czech Republic, Japan, UK, Portugal, Russia, Croatia, China, Brazil, USA, France, Slovakia, Mexico and Spain, GOM organised the same in India in the month of April in association with APM Technologies. The workshop held in Pune – the hub of auto manufacturers and their vendors, was attended by more than 100 participants from companies like Bajaj, Force motors, General Motors, JBM, John Deere, Magna, Mahindra & Mahindra, Tata Motors, Tata Technologies, Volkswagen and many others including IIT Bombay and other technical institution from the country.

The workshop was focused on the issues that sheet metal industries are facing today and solution to those issues through optical metrological equipment produced by GOM GmbH, Germany. APM Technologies, the face of GOM in India arranged live demonstration of equipments for Tool and die optimisation, tracking and virtual assembly, Quality control inspection of sheet metal parts and strain measurement for material analysis and all under one roof.

The show started with the speech of Mr. Anil Gupta, the CEO, APM Technologies wherein he discussed changing trends of quality control practices in industry, followed by the presentation by Mr. Subramanya Prasad from Volkswagen and shared his experience with GOM for enhancing level of quality and discussed issues such as tool maintenance and optimisation. After his presentation Mr. Pieter Schuer (Managing Director GOM Asia) acquainted the participants with the latest developments in the field of optical metrology and Dr. Narasimhan (Professor IIT Bombay and Head SMFRA), who took the show to next level through enormous amount of knowledge he shared regarding material testing and analysis using optical metrology. He also shared the parameters that affect the quality of sheet material and method of analysis of material properties using Forming Limit Curve.

The second half was an interactive session wherein live demonstration of technology was shown with a focus on various challenges faced by sheet metal industry i.e. quality control of components such as dimensional analysis, fitting of components, feature optimisation, Curve based analysis, tool and die optimisation and maintenance, virtual assembly of parts for visualisation and analysis of interference, gap and flush, live tracking for positioning of components without fixtures in prototype stage, measurement of strain in for ability process to understand material behaviour subjected to various kinds of load/applications. The participants remarked the workshop as informative and beneficial as it was focused on practical issues what they are facing today. More such events on castings, plastics, tool and dies, turbine blades,etc. are in line to be held across the country to spread awareness among various industries.

Related Stories

Germany's Barnes Molding Solutions Opens $30 Mn Greenfield Facility in Pune

New Chakan plant strengthens Barnes Molding Solutions’ Asia strategy with local manufacturing and service capabilities.

Read more

Hindustan Power Secures 1 GW Solar and 0.75 GWh Storage Projects in 2025

Hindustan Power has added nearly 1 GW of solar capacity and over 0.75 GWh of battery storage through multiple projects secured across Indian states in 2025.

Read more

KEC International Wins Rs 10.5 billion Orders across EPC Businesses

KEC International has secured Rs 10.5 billion in new orders across renewables, civil, T&D, and cables, including its maiden wind energy BoP project in India.

Read moreRelated Products

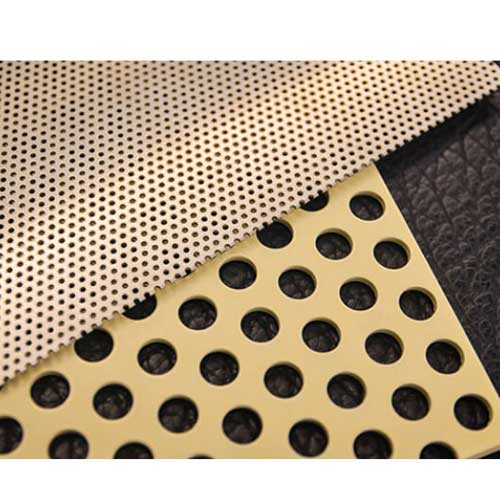

Perforated Sheets

Raj Filters & Wiremesh Pvt Ltd offers a wide range of perforated sheets.

Fibro Die Mounted Cam Unit

Fibro India Precision Products Pvt Ltd offers a wide range of fibro die /mounted cam unit. Read more

Metal Pallets

Metal Impacts manufacturers a high quality steel pallets that are available in different sizes, forms and construction designs to meets the needs and requirements of our huge client base. These ste Read more