Schedule a Call Back

Corrosion Prevention by Cathodic Protection

Technical Articles

Technical Articles- Dec 23,13

External corrosion of underground/under water structures is an electrochemical phenomenon. The control of this corrosion process can be achieved by employing Cathodic Protection System. The state-of-the-art cathodic protection system can be implemented by distributing uniform current over the entire surface to be protected to achieve uniform corrosion protective potentials.

Corrosion - one general definition of corrosion is the degradation of a material through environmental interaction. Most metals are thermodynamically unstable and will tend to seek a lower energy state, which is an oxide or some other compound. The process by which metals convert to the lower-energy oxides is called corrosion.

Corrosion of most common engineering materials at near-ambient temperatures occurs in aqueous (water-containing) environments and is electrochemical in nature. The aqueous environment is also referred to as the electrolyte and, in the case of underground corrosion, is moist soil. The corrosion process involves the removal of electrons (oxidation) of the metal [Equation (1)] and the consumption of those electrons by some other reduction reaction, such as oxygen or water reduction [Equations (2) and (3), respectively.

Both oxidation and reduction reactions are necessary for corrosion to occur. The oxidation reaction causes the actual metal loss but the reduction reaction must be present to consume the electrons liberated by the oxidation reaction, maintaining charge neutrality.

Corrosion Prevention

Coating: Initial attempts to control corrosion relied on the use of coating materials and the reasoning that if the surface of structure metal could be isolated from contact with the surrounding earth, no corrosion could occur. Furthermore, a coating would be completely effective as a means of stopping corrosion if the coating material is capable of providing 100 per cent barrier from water and oxygen. Cathodic Protection (CP): Unfortunately coatings cannot provide 100 per cent corrosion prevention for industrial structures (i.e., pipelines, underground tanks, submerged jetty structures, etc), as they do not ensure complete holiday free layer, in terms of size/geometry of the structure, installation process and time.

CP is a technique to reduce the corrosion rate of a metal surface by making it the cathode of an electrochemical cell. At the anodic areas, current flows from structure into the surrounding electrolyte (soil or water) and the structure corrodes. At the cathodic areas, current flows from the electrolyte onto the structure surface and the rate of corrosion is reduced. In light of the above, it becomes obvious that the rate of corrosion could be reduced if every bit of exposed metal on the surface of a structure could be made to collect current.

Conclusion

Over the years the cost of implementing a corrosion control system has proven to be extremely beneficial in the reduction of leaks/material loss and extension of the useful life of structure. Whether by using coating alone or coating with Cathodic Protection (CP), owners have obtained very good results when sound corrosion engineering is implemented. The additive cost for corrosion control typically represents a very small percentage of initial construction costs. With this in mind corrosion control systems should be implemented as a standard operating procedure for all buried/submerged systems to enhance the life of the asset. Universal Corrosion Prevention India (UCPI) is a company based on a group of dynamic and highly experienced IIT Engineers in the field of Corrosion Prevention and Cathodic Protection to safeguard important infrastructures, installations and facilities from corrosion.

The company offers the following services:

- Cathodic protection jobs for pipelines

- Cathodic protection (impressed and sacrificial type) jobs for mounded bullets, vessels, tanks, ALDS, etc

- CP of jetty, submerge structures

- Trouble shooting and rectification of corrosion related problems

- Annual monitoring and maintenance related to corrosion and cathodic protection, etc.

- Manufacture of reference electrodes, junction boxes, anodes, etc.

UCPI clients are eminent names like IOCL, HPCL, KMC, RITES, Aditya Birla Group, TATA Chemicals Ltd., Maruti Suzuki India Ltd., Simplex, ITD, SALPG, etc.

(Universal Corrosion Prevention India, Old Berhumpur Road, Dakshin Para, Ranaghat, Nadia, West Bengal 741 201. Tel: 03473-251044. Mobile: 093326-01292. Email: universal.cpi@gmail.com)

Related Products

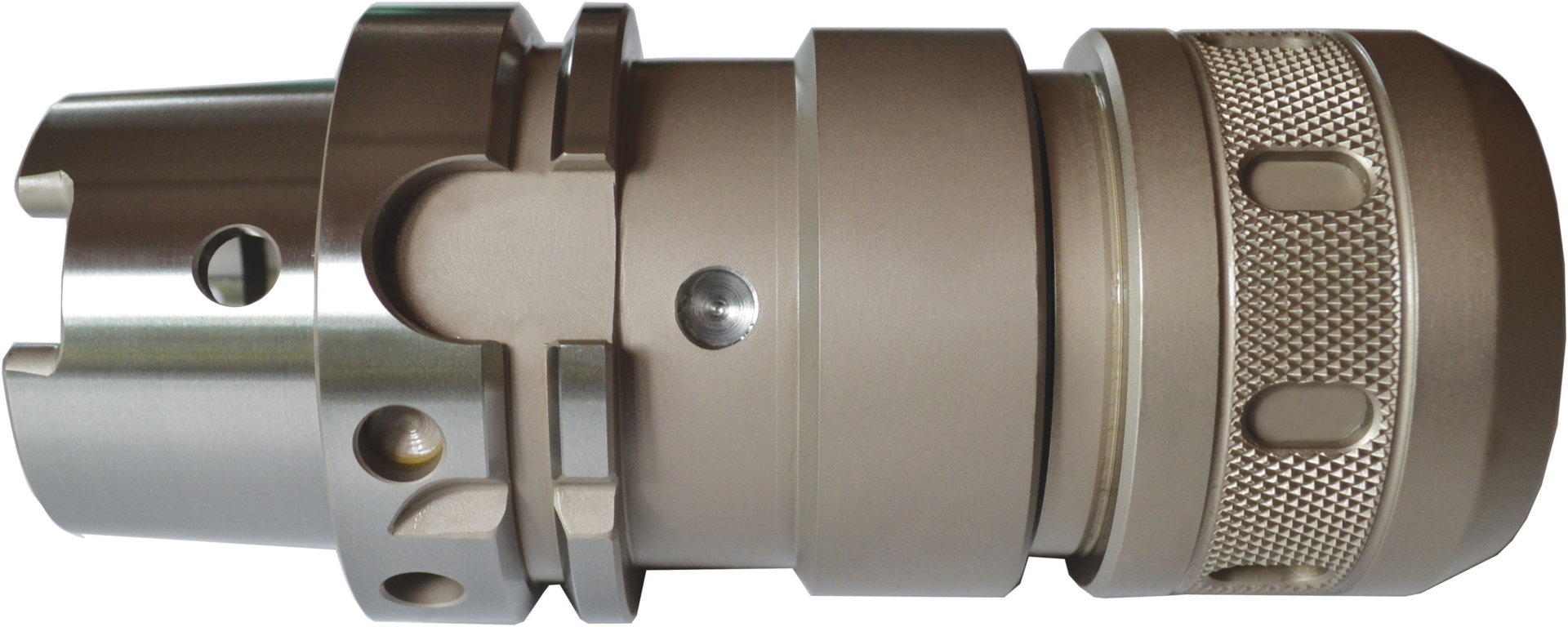

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.