Schedule a Call Back

Coiling It Right

Technical Articles

Technical Articles- Jan 03,12

At times making the right product the right way is more important as a long-term strategy for a small scale enterprise is what Huned Contractor discovers when he meets Naroor Rajan of Efficient Toroidal Coil Corporation in Pune

At times making the right product the right way is more important as a long-term strategy for a small scale enterprise is what Huned Contractor discovers when he meets Naroor Rajan of Efficient Toroidal Coil Corporation in Pune

"We don't do any marketing of our products." It's an odd statement to make for an engineering company that has to survive in times of fierce competition. But after Mr Naroor Rajan, CEO of the Pune-based Efficient Toroidal Coil Corporation, explains his business model, it becomes apparent why he doesn't have to indulge in tom-tomming about his enterprise. The company is one of the leading manufacturers of wire wound electric components such as toroidal transformers, current transformers, servo potentiometers, load banks, position sensors and high wattage resistors with reputed clients in its portfolio that includes Telco, Bajaj Auto, Indian Aluminium Ltd, Indo Gulf Corporation, Aplab Ltd, The Indian Card Clothing Ltd, Monga Electronics, Seshasayee Paper Board Ltd, among many others.

More than that, what gives Efficient Toroidal an edge above the rest of the companies engaged in a similar line of activity is that it is also a supplier to the Air Force 9 Base Workshop and other government organisations such as the Central Water & Power Research Station and Bharat Electronics. In fact, the toroidal transformers made by the company are a part of the Sukhoi 30 aircrafts. What exactly are toroidal transformers? A coil of insulated wire in a doughnut shape (usually with a core of iron or similar metal) is an example of a toroidal object. These are used as inductors in circuits such as low frequency transmitters and receivers because they possess higher inductance and carry greater current than similarly constructed solenoids.

Also used as transformers in main power supplies, toroidal coils reduce resistance due to the larger diameter and smaller number of windings. The magnetic flux in a toroid is confined to the core, preventing its energy from being absorbed by the nearby objects. Explaining why toroidal transformers are better than the conventional ones, Rajan states, "Toroidal transformers offer many advantages over standard laminated power transformers because they provide quiet, efficient operation with very low stray magnetic fields. Their small size and weight support a package that is easy to design into any application." For Rajan, this foray into a niche segment came out of his strong desire to be different.

Also used as transformers in main power supplies, toroidal coils reduce resistance due to the larger diameter and smaller number of windings. The magnetic flux in a toroid is confined to the core, preventing its energy from being absorbed by the nearby objects. Explaining why toroidal transformers are better than the conventional ones, Rajan states, "Toroidal transformers offer many advantages over standard laminated power transformers because they provide quiet, efficient operation with very low stray magnetic fields. Their small size and weight support a package that is easy to design into any application." For Rajan, this foray into a niche segment came out of his strong desire to be different.

The story goes back to the late seventies when Rajan decided to give shape to his technical aptitude by doing a diploma course at the Kohinoor Technical Institute in Mumbai, following which he started working as a helper in an engineering firm on a salary of Rs 5 per day. In 1982, he joined the Bhilai Steel Plant and worked on a project that was the first of its kind in Asia. Fate brought him to Pune where he worked with Patel Analog, manufacturers of coil winding, bushing and transformer winding machines, for 14 years. "It was during this stint that I first came across the concept of toroidal transformers in an American magazine. I found it strange that while toroidal transformers were in common use in the US and other countries, no one was making them in India, mostly because of the cost factor," Rajan says.

The idea of making these transformers gripped him hard and in 1994 he decided to become an entrepreneur. As to how Efficient Toroidal became an approved supplier for the Air Force has an interesting background too. "When the Air Force decided to use toroidal transformers, it called 14 transformer manufacturing companies to bid for the order. Considering the order size and the fact that it would require a focused manufacturing platform, 13 companies walked out and I was the only one left," Rajan recalls. But that one opportunity which Rajan seized has led to good dividends over the years with the company setting a high benchmark for its toroidal transformers and getting recommended in several OEMs across India.

The idea of making these transformers gripped him hard and in 1994 he decided to become an entrepreneur. As to how Efficient Toroidal became an approved supplier for the Air Force has an interesting background too. "When the Air Force decided to use toroidal transformers, it called 14 transformer manufacturing companies to bid for the order. Considering the order size and the fact that it would require a focused manufacturing platform, 13 companies walked out and I was the only one left," Rajan recalls. But that one opportunity which Rajan seized has led to good dividends over the years with the company setting a high benchmark for its toroidal transformers and getting recommended in several OEMs across India.

However, Rajan concedes that the growth of his business would have been stunted if he had had to depend only the government orders. "Fortunately, toroidal transformers are used in several sectors now, including medical healthcare equipment, main power supplies or any product that calls for critical power management. We therefore have a steady stream of orders from the private sector," Rajan says. The company makes about 1,000 pieces of toroidal transformers of 15 kVA every month apart from rheostats of up to 10,000 watts and wire wound singe turn potentiometers in the range of 1 watt to 12 watts. With its team of 12 skilled people, Rajan says that he doesn't even use 10 per cent of the actual production capacity.

Elaborating about his business model, Rajan informs that what has always kept Efficient Toroidal on a steady wicket is that there are no loans to pay and the overheads are kept low. "We have all the production facilities with us that include coil winding machines, oven, drilling machine, grinder, a transformer testing bench, multimeters, linearity testing instruments, frequency generators, and so on, so that there is not much that we have to outsource and pay for," he says. More importantly, Rajan's passion for research and development has meant that he prefers to create customised transformers rather than getting into mass production and selling them as off-the-shelf products. "Transformers interest me more than making money," he quips.

(Contact Details: Efficient Toroidal Coil Corporation, Unit 11, Electronic Sadan I, Bhosari, MIDC, Pune - 411 026. Tel: 020-27129614. Email: efficienttoroidal@yahoo.com. www. efficienttoroidal.com)

Related Products

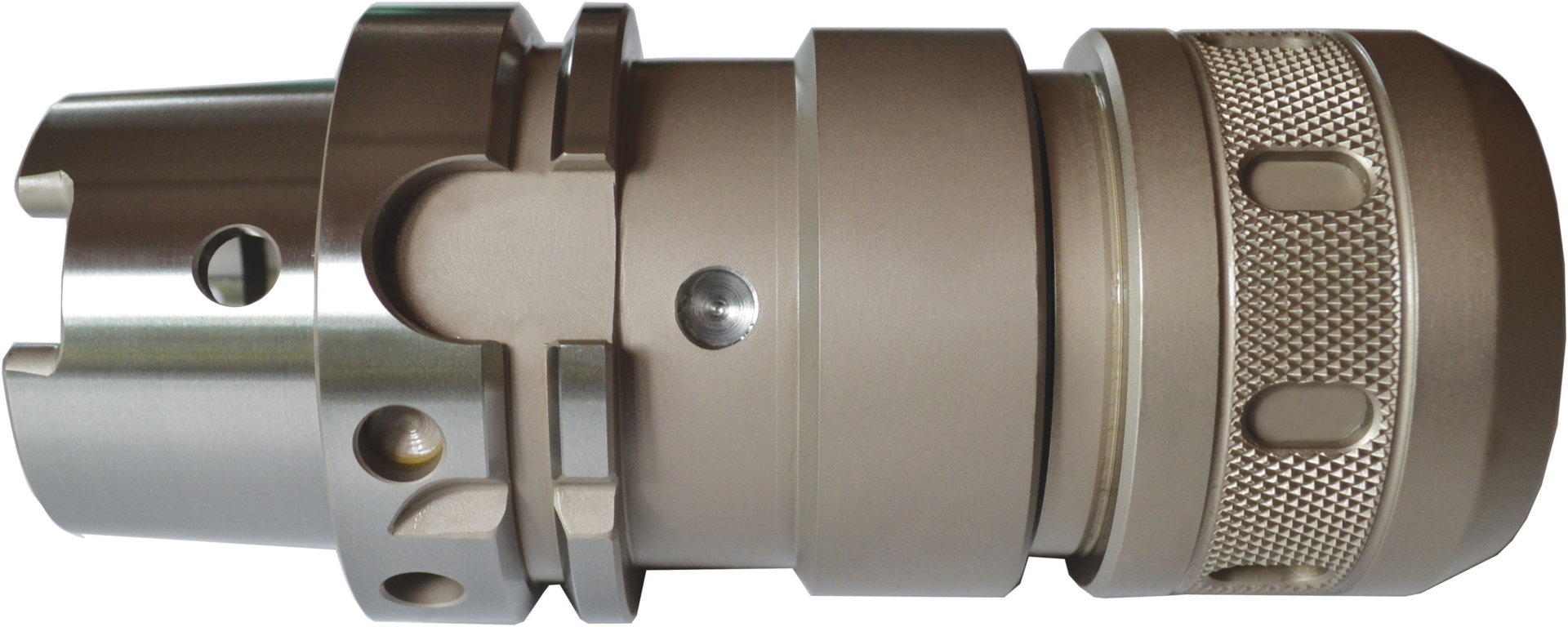

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.