Schedule a Call Back

Buyer's Guide to Surge Protection

Technical Articles

Technical Articles- Sep 16,10

A brief overview on why Surge Protection is important

Most people are aware of the fact that electrical and, in particular, electronic equipment can be damaged or destroyed by lightning. This is a dramatic and probably the most extreme example of surge damage, and equipment definitely needs to be protected from lightning damage, but surges and transients can also be produced by equipment located inside a building.

Most people are aware of the fact that electrical and, in particular, electronic equipment can be damaged or destroyed by lightning. This is a dramatic and probably the most extreme example of surge damage, and equipment definitely needs to be protected from lightning damage, but surges and transients can also be produced by equipment located inside a building.

Surges and voltage transients are defined as abnormally high pulses of voltage that substantially exceed the normal operating voltage of a circuit. They are generally random in nature and may last anywhere from tens of nanoseconds (a billionth of a second) to around one millisecond (a thousandth of a second). Advances in semiconductor processing technology, producing devices with smaller and smaller geometries, have also limited the ability of these devices to absorb transient energy. As such devices are designed into electronic equipment, the overall susceptibility of the system increases. With billions of dollars' worth of equipment now being lost each year to the effects of electronic overstress, effective power conditioning is absolutely necessary as a part of system design.

Lightning Surges

There is absolutely no way to protect equipment in a part of a building that gets a direct hit by lightning. Usually, however, when a building or a utility pole gets hit, the equipment itself does not receive the direct discharge; the equipment receives a surge conducted through the building wiring. Research has shown that because of arc-over at the service entrance and within the building wiring, the maximum voltage that reaches a 240 V outlet is 6000 V. It has also been determined by the same research that the maximum current is 3000 A. So, although lightning itself has millions of volts, we don't get millions of volts jumping out of the 240 V outlet. We also now have an idea of what a surge protector must be able to reliably handle in order to protect equipment from lightning damage.

There is absolutely no way to protect equipment in a part of a building that gets a direct hit by lightning. Usually, however, when a building or a utility pole gets hit, the equipment itself does not receive the direct discharge; the equipment receives a surge conducted through the building wiring. Research has shown that because of arc-over at the service entrance and within the building wiring, the maximum voltage that reaches a 240 V outlet is 6000 V. It has also been determined by the same research that the maximum current is 3000 A. So, although lightning itself has millions of volts, we don't get millions of volts jumping out of the 240 V outlet. We also now have an idea of what a surge protector must be able to reliably handle in order to protect equipment from lightning damage.

Inductive Surges

When a piece of equipment that contains an inductive element such as a motor, transformer or coil is switched off, a "back-emf" is produced. This back-emf, which is caused by the collapse of the magnetic field, is the result of one of the most basic laws of electricity, Faraday's Law of Induction. The voltage thus produced can be many times the original voltage applied to the inductive element before it was switched off, although the duration of these surges (or transients) is very short.

When a piece of equipment that contains an inductive element such as a motor, transformer or coil is switched off, a "back-emf" is produced. This back-emf, which is caused by the collapse of the magnetic field, is the result of one of the most basic laws of electricity, Faraday's Law of Induction. The voltage thus produced can be many times the original voltage applied to the inductive element before it was switched off, although the duration of these surges (or transients) is very short.

Such inductively produced transients may not be as energetic as a lightning strike, but similarly damage and degrade electronic equipment when they find their way onto the circuit board. Inductively produced transients, which travel throughout building wiring, are commonly produced by air conditioning and refrigerator motors cycling on and off, and by other equipment containing inductive elements.

It is plainly desirable to protect equipment from lightning surges and from inductive transients produced within a building. This is especially true if the equipment is very costly or is in an application, which absolutely must remain operational. Protecting equipment with quality power conditioning not only prevents catastrophic failures but also improves the reliability of electronic equipment by preventing degradation and premature failure of integrated circuits.

Types of Surge Protectors

All surge protectors can be put into two main categories based on the way they operate. Most surge protectors operate by shunting energy, but SurgeX operates in series with the electric service.

Shunt Protection

Almost all shunt surge protectors rely on MOVs (metal-oxide varistors) connected in such a way as to shunt surge energy to ground. An MOV is a type of semiconductor device, which "turns on" when the voltage across it exceeds a certain value. MOVs are about the size of a coin, and cost about that much. When a surge appears at the terminals of an MOV its resistance drops as the voltage across it exceeds the threshold and it conducts the surge current, diverting the surge to the neutral wire and/or the ground wire. Shunt protection is therefore diversion technology - the surge is diverted from the hot wire to the neutral wire and/or the ground wire.

MOV-based surge protectors have been in use since the 1970s and have always had serious limitations that compromise their effectiveness and reliability. Of prime concern is the fact that MOVs have a lifetime "joule" rating. The joule rating for an MOV means that when a particular MOV has received the specified maximum amount of energy, it no longer works! This could be the result of one or two large surges or several small surges. Therefore, when MOVs are used in surge protectors, a strict replacement schedule is necessary. It is like being without a gas gauge in your car - you never know when you are going to run out of gas, so you have to keep putting more gas in your car just in case! Lack of replacement can have very serious results - MOVs have been known to cause fires.However, the overwhelming weakness of shunt protection is that it does not handle or contain transients and surges in any way, the energy is simply diverted to the neutral wire and/or the ground wire. This is a serious problem because diverting surges to ground can cause damage to interconnected equipment. This is because the safety ground is also the system ground in audio, video and computer systems. The surges travel along the interconnecting cables and capacitively couple onto the signal wires! All wires including building wiring and interconnect wiring have impedance which will generate a substantial voltage when the thousands of amps of surge current are suddenly dumped onto such wiring. This is Ohm's Law. One of the worst-case examples of this problem is that of interconnected computers because computers are often interconnected by long datacomm cables, and plugged into 240V outlets at very different parts of a building.

The important points to remember for shunt type protectors are:

- Cheap and simple to produce

- Limited lifetime, and

- Contaminate system ground.

SurgeX Protection

SurgeX protection operates in series with the hot wire and works by blocking and containing transients and surges rather than by diverting them to ground. This has the dual advantages that the surge protector does not have to handle thousands of amps of surge current and, most importantly, system ground is not contaminated.

The first line of defence in the SurgeX system, and key to SurgeX protection, is the massive surge reactor, which is in series with the hot wire. The surge reactor filters out small transients, slows down larger surges (both are extremely fast), and limits the surge current. All current which passes to equipment connected to a SurgeX product passes through this filter. The second part of the SurgeX system is an electronic circuit which tracks, clamps and contains the residual surge energy after it has been slowed down by the surge reactor. This energy is then released slowly to the neutral wire, not the ground wire. In this way, the safety ground is never contaminated, and interconnected equipment is not put at risk when a surge comes in on the power lines feeding the equipment.

SurgeX contains no sacrificial components (such as MOVs) and can withstand thousands of the largest surges normally found on 240V wiring (6000V, 3000A). The SurgeX system also has superior clamping because it tracks the power wave and utilizes active clamping. This combination of passive and active technologies is extremely effective and SurgeX has been used in the most demanding industrial and commercial environments with exemplary performance. It has protected equipment when there have been direct lightning hits on buildings, and has also protected equipment from data errors caused by transients produced inside factories.

Furthermore, the same technology used inside all SurgeX products meets the highest level of Endurance Testing that is available - the buyer's absolute guarantee of performance. And, SurgeX products comply with UL 1449 Second Edition safety testing without using any fuses or other devices that can suddenly shut down equipment without warning or leave you without protection.

The important points to remember for SurgeX power conditioning are:

- Unlimited lifetime

- No sacrificial components

- Unsurpassed voltage clamping

- Safety and system ground are not contaminated, and

- UL 1449 Adjunct Testing.

Caution: Do not confuse the endurance (adjunct) testing discussed in this article with the safety testing that UL are usually associated with. UL 1449 certification does not automatically mean that a product also passes the adjunct endurance testing (which is optional), it only means that the product has passed safety requirements.

All SurgeX products are certified Grade A, Class 1,

Mode 1:

- Survived 1000 surges of 6000V, 3000A - no failures or degradation

- Let-through voltage did not exceed 330V, and

- Ground was not contaminated.

(Article courtesy: R & S (India) Electronics Pvt Ltd, Mumbai, representative in India for SurgeX products.

Contact: Tel: 022-26732593. Fax: 91-22-26732594. Email: mumbai@rns.co.in)

Related Products

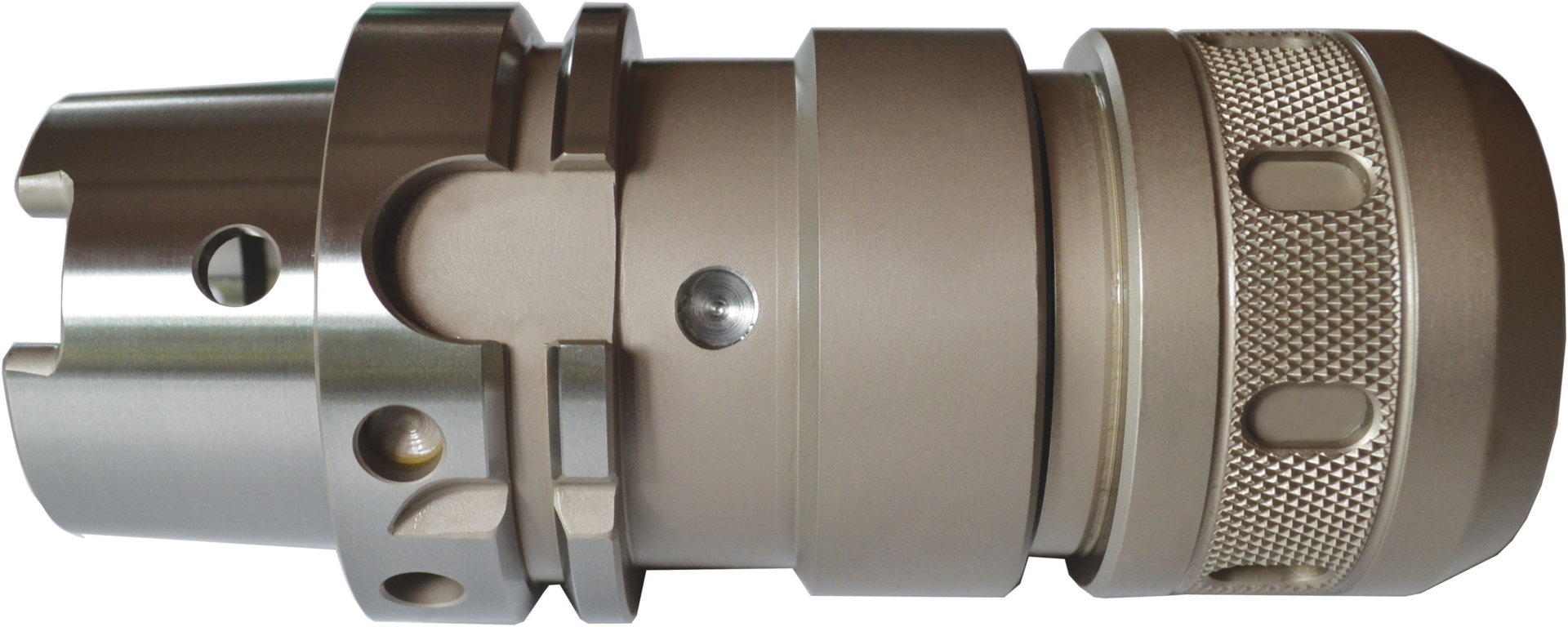

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.