Schedule a Call Back

Safe Selection

Technical Articles

Technical Articles- May 01,18

A detailed tour of understanding how critically important intrinsically safe devices are, for fire detection from Rohit Harjani.

What is Intrinsic Safety?

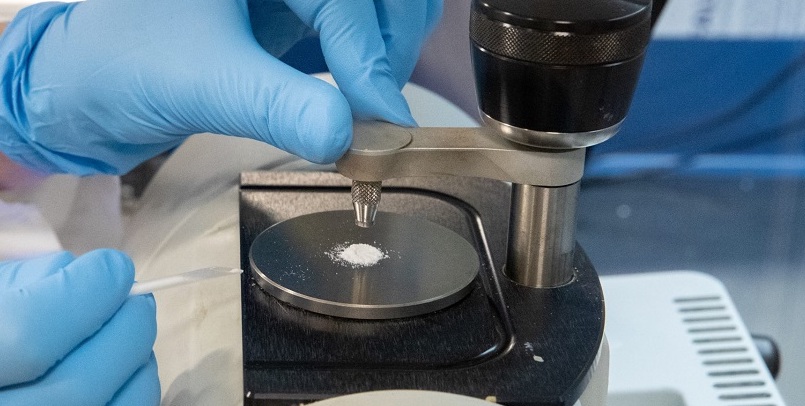

For an electrical product to be ‘Intrinsically Safe’ it must be incapable of igniting an explosive atmosphere by either spark or heat. This is achieved by ensuring only low currents and voltages enter the hazardous area, and therefore the whole circuit must be considered, not just the device in isolation.

An ‘Intrinsically Safe Circuit’ therefore must restrict the electrical and thermal energy such that ignition of a hazardous atmosphere (explosive gas or dust) cannot occur.

Understanding Hazardous Areas

The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR), defines a hazardous area as: Any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers.

EN60079-10-1 – explains that hazardous areas can be classified into zones based on the amount of time explosive gases, vapours and mists can be found in the atmosphere.

- ZONE 0: An area in which an explosive gas atmosphere is present continuously or for long period.

- ZONE 1: An area in which an explosive gas atmosphere is likely to occur in normal operation.

- ZONE 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time. There is also zone classification for combustible dust:

- ZONE 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

- ZONE 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

- ZONE 22: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Intrinsically safe device categories

When selecting an intrinsically safe device, installers must ensure that the product has the appropriate certification for the zone required. Equipment categories are different to zones. How the zones and categories correspond is shown below:

- ZONE 0 or ZONE 20 = Category 1 equipment

- ZONE 1 or ZONE 21 = Category 2 equipment

- ZONE 2 or ZONE 22 = Category 3 equipment

It should be noted that: Category 1 equipment is also suitable for zones 1, 2, 20 and 22; Category 2 equipment is also suitable for zones 2 and 22.

For example, Hochiki’s SLR-E-IS and DCD-1E-IS are certified for use in Category 1. This means they are suitable for zones 0, 1, 2, 20, 21 and 22.

Standard device and intrinsically safe device difference

Aesthetically, the shape and size of an intrinsically safe smoke detector, heat detector or multi sensor can be very similar to standard devices, however, you will notice additional warning information and zone information printed on an intrinsically safe device.

You might find that some devices are non-pulsing, meaning that the LED will not flash when polled. This is primarily because an intrinsically safe device needs to operate at lower voltage than a standard device in order to eliminate any possibility of igniting the explosive atmosphere. It is important that there is no chance of ignition in normal operation or in fault conditions.

The low power levels also mean that there is no chance of receiving an electric shock due to excess thermal energy and arcing. And remember, when installing an intrinsically safe device, it is crucial that an intrinsically safe mounting base is used.

Difference between flame proof and intrinsically safe

Flameproof equipment must be contained in a box strong enough to contain an internal explosion without damage to the box or transmittance outside of the box. The surface must also remain cool enough, not to be able to ignite the explosive atmosphere. In addition, when flameproof equipment is interconnected, flame proof wiring must be used. Flameproof wiring is acceptable if high power is unavoidable, however it is not acceptable to use this method in zone 0 hazardous areas.

Intrinsically safe devices operate at much lower power; even the quiescent current is much lower. This therefore means that, depending on the certification, an intrinsically safe device can be used in all classifications of hazardous area.

Barriers and Modules

We have established that standard devices cannot be used in hazardous areas as there is a risk of ignition; therefore, low current intrinsically safe devices must be used instead. Ofcourse, buildings do not tend to be completely hazardous; they will have safe areas that require standard devices and hazardous areas that require intrinsically safe devices.

Therefore, an intrinsically safe compatible module is designed to interface between the two. Some modules also provide line monitoring for open or short circuits on the wiring connected to both the safe and hazardous areas. It is important to note that a module does not reduce the current in any way, a module is simply used to interface between standard devices and intrinsically safe devices.

This means that you must also use an intrinsically safe barrier; it is the barrier that reduces the power that enters the hazardous area. Both the module and the barrier must therefore be installed in the safe area.

SIL approved products

It is important to note that SIL approved products are not the same as intrinsically safe products. SIL approved products are for use in high risk industries, intrinsically safe products are for use in classified hazardous areas. However, you may find that some manufacturers, offer products that have both SIL and IS certification.

SIL is the acronym for ‘Safety Integrity Level’. This is a system used to quantify and qualify the requirements for safety instrumented systems. There are four different SIL levels; SIL1, SIL2, SIL3 and SIL4. The international Electro-Technical Commission (IEC) introduced the following industry standards to assist operators with quantifying the safety performance requirements for hazardous operations:

IEC 61508 functional safety of electrical/electronic/programmable electronic safety-related systems.

IEC 61511 safety instrumented systems for the process industry sector.

These standards have been widely adopted in the hydrocarbon, oil and gas, petrochemical, transport and process controlled industries as a means of improving safety and availability of safety instrumented systems. As such, these industries are increasingly specifying the requirement for SIL approved fire detection equipment.

Compliance

There are a number of intrinsically safe fire detection products on the market. To remain legally compliant, please ensure that the products you select have been certified under the following directives:

- EU 305/2011

- ATEX Directive 94/9/EC*

- IECEx

Rohit Harjani is the Country Manager, Indian Sub-continent region for Hochiki and is responsible for company’s business operations in India, Bangladesh, Bhutan, Nepal and Sri Lanka. Having gained expertise in the domain of fire detection systems, Rohit has more than 16 years of global industry experience. Hochiki Europe is one of the worlds' leading manufacturers of quality fire detectors and alarms for commercial and industrial applications, distinguished by its experience and expertise in this field since 1918. For more details contact on email: info@hochiki.in

Related Stories

Will solar manufacturing glow in India as renewable energy demand surges?

While India has successfully increased domestic solar module production, import of solar cells remains high. As India plans to add 60-65 GW of solar capacity, will it be a sunshine moment for solar ..

Read more

A Tariff here, a tariff there

The proposal by Trump to impose tariffs has stirred the pot. Manufacturing will be the most affected. But, if followed through well, it can increase the global wealth, as well as wealth distribution..

Read more

IISc discovers method to break down biofilm barriers using cow's gut enzyme

To break down the biofilm, the IISc team focused on using enzymes that degrade polysaccharides.

Read moreRelated Products

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.

Push Button Safety Quick Release Coupling

Siemag introduces the all new push button safety quick release couplings. Read more