Schedule a Call Back

Ricoh increases efficiency by using 3D printed thermoplastic tools

Technical Articles

Technical Articles- Nov 01,17

Related Stories

Manufacturing to Drive 46% of Industrial Leasing by 2027: JLL

JLL forecasts manufacturing leasing to reach 34 mn sq ft across top cities.

Read more

HHV Advanced Technologies invests in EON Space Labs for imaging tech growth

HHV Advanced Technologies joins EON Space Labs as investor and partner to scale AI-driven imaging payload manufacturing and launch ultra-lightweight space telescope MIRA in 2025.

Read more

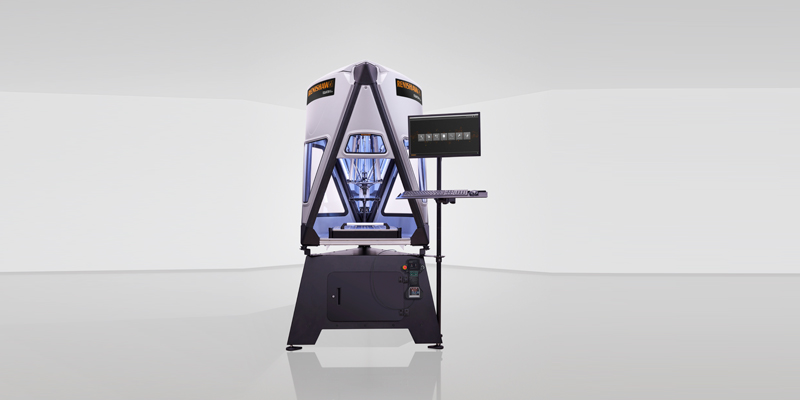

Renishaw Unveils Equator–X 500 Dual-Method Gauging System

Equator–X 500 dual-method system extends the Equator range of versatile gauges for shop floor process control, high-speed measurement and quality assurance

Read moreRelated Products

Ultrasonic Thickness Gauge

BSK

Technologies offers a digital portable ultrasonic thickness gauge, Model

TM-8810.

Digital Pressure Gauge

Atlas Industrial Stores offers a wide range of weatherproof digital pressure gauge.

Stress Analysis Strain Gauges

HBK India (Bruel & Kjaer) offers a wdie range of stress analysis strain gauges.