Schedule a Call Back

Fluid power industry: Aiding 'smart' growth

Technical Articles

Technical Articles- Feb 01,18

Related Stories

Enterprises should not rush to adopt disruptive technologies

Automation is helping organisations rise to the challenge of doing more with shrinking resources and budgets.

Read more

Fluid power industry: Aiding 'smart' growth

With the buzz word being ‘smart’, Dr S Prasanna Kumar deliberates on disruptive technologies that would contribute to the growth of fluid power technology

Read moreIIIT-Hyderabad unveils report on disruptive technologies

The International Institute of Information Technology, Hyderabad (IIIT-H) , in association with TalentSprint, unveiled a report on “Demand for expertise in disruptive technologies amo..

Read moreRelated Products

Power Conversion Systems

POM Systems & Services Pvt Ltd offers a wide range of

PCS power conversion systems energy storage.

Hot Water Generators

Transparent Energy Systems Private Limited offers a wide range of Hot water generators - Aquawarm Superplus.

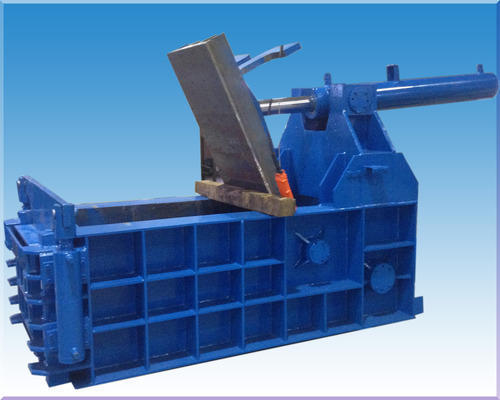

Scrap Baling Press

Fluid Power Machines offers hydraulic scrap baling press. Read more