Schedule a Call Back

The future belongs to Industry 4.0

Interviews

Interviews- Dec 01,17

…says Hans Bangert, Managing Director of Bosch Rexroth (India) Ltd since July 2015, who believes that the combination of Indian IT expertise with German engineering strength would be mutually beneficial for developing solutions for Industry 4.0. With this strong international background, combined with broad experience in leading development projects and production entities, Bangert has been the Managing Director for Bosch Group companies since 15 years. In this interview with IPF, he discusses trends in manufacturing industry and growth plans for his company.

As MD of Indian operation of Bosch Rexroth, you have completed two years. How has been your experience so far?

During my career of over 35 years for the Bosch Group, I had the great opportunity to manage regional units in different countries worldwide. Every time I had to face a new culture, new colleagues and all kind of challenges.

In India, we see huge potential and a sound future. The performance of our Indian subsidiary really impressed me. We have a modern, state of the art production facility and a great team of experienced, dedicated and very skilled associates. This continues to be a good basis for me as a ‘newcomer’ in India. Initiatives and policies from the government - eg tax reforms, infrastructure development etc - are big boosters creating an attractive business environment for the industry. The new world of connected industry and automation of processes is just around the corner and has already started in some areas. However, it remains difficult to get a reliable prediction for the ‘full swing’ market entry of these new technologies.

Kindly brief us about Bosch Rexroth business operations in India.

Bosch Rexroth commenced operations in India in 1974 under the aegis of Bosch Rexroth AG and, over the years, has thrived to become one of the leading companies in India specialising in the field of drive and control technologies. It designs, develops and distributes components and systems in the areas of mobile and industrial hydraulics, electric drives and controls, linear motion and assembly technology. The products find application in major industries like plastics, steel, bulk materials handling, railways, construction machinery, agricultural and farm machineries, cutting machine tools and presses, automotive, food and packaging, textiles, etc.

Which industries are the main demand drivers for Bosch Rexroth products & solutions in India?

Bosch Rexroth has positioned itself as the drive and control company and is a partner for industrial applications (machinery applications and engineering and factory automation) and mobile applications. The company offers a wide range of industry specific solutions in various technology areas and as mentioned above, they find major applications in industries including steel, construction, machine tools, printing machines, bulk materials handling, railways etc.

How is Bosch Rexroth approaching Industry 4.0 - both as a user (within its own factory) and as supplier of Industry 4.0 compliant technologies to its customers?

Industry 4.0 – or connected industry – is referred to as the 4th industrial revolution.

Bosch Rexroth is a key proponent and provider of Industry 4.0. It is offering its customers the solutions that will allow them to improve the flexibility and productivity of their factories. Bosch Rexroth is not only a lead user of Industry 4.0 but is a lead supplier. We embraced Industry 4.0 early, which has allowed us to grow with it and gain a strong understanding of its workings and capabilities.

Whether a tool manufacturer or supplier, equipment operator or factory integrator, Bosch Rexroth offers support where it is needed to take advantage of the better resource allocation, higher efficiency, individuality and profitability Industry 4.0 represents. Bosch Rexroth delivers many intelligent industrial automation solutions for the connected industry, eg ‘Open Core Engineering’. Open Core Engineering revolutionises software engineering. The open core interface allows machine manufacturers for the first time to access the core of their control systems to configure and modify variables as well as motion and PLC functions.

Use of automation is increasing across industries. What does it mean to Bosch Rexroth?

Automation is growing considerably in India. We aim at establishing Bosch Rexroth as a leading solution provider in automation. We provide integrated one stop solutions for automation applications and services (hydraulics, linear motion & assembly technology and electric drives & controls). The expansion of our product portfolio in the last few years has opened new avenues, especially in mid-size automation. We are continually working towards new segments with this portfolio, thus offering our customers a complete range of solutions.

What do you mean by 'Connected Hydraulics'? How it is different from conventional hydraulics and what are its advantages?

We are currently experiencing the transition from classic, analog hydraulics to largely digital networked fluid technology. Modern, electronified hydraulic solutions can do anything that conventional hydraulics can do and also have new, modern features: simple engineering, fast start-up, high efficiency and better availability.

The challenge is to combine the advantages of hydraulics such as robustness, safeguards against overloading and power density with the advantages of electronic intelligence. In this regard, we have made important progress in recent years. This allows for much simpler dealing with fluid technology and unprecedented flexibility in terms of use.

How is Industry 4.0 shaping up in India? Are Indian manufacturers open to Industry 4.0 technologies?

The future belongs to Industry 4.0 - where the virtual world of information technology, the physical world of machines and the Internet will converge. It centers on the increasing integration of all areas of industry which is made possible by information technology. Connected production helps maintain and increase competitiveness. Connected industry creates new opportunities

for manufactures and OEMs through merging the key elements which can result in rapid transformation of the industry.

India has travelled through a rapid industrialisation process which has undeniably led to tremendous growth of manufacturing, infrastructural and IT related industries in the country. India has well-recognised the importance of manufacturing for future requirements and the implementation of such concepts will bring forth great potential for growth in the coming decade.

What are the emerging trends in drive and control technology?

Industry 4.0 (connected industry), coupled with machine safety, energy efficiency, integrated axis controls and explosion protection are some of the new development trends seen in this category in India. Market fluctuations have shifted the trends in the market. Customers are increasingly looking for one single source that can cater to all their drive and control needs. Hydraulics, electro-hydraulics and electro-mechanics will all remain relevant drive technologies based on their specific advantages. A demand for new solutions within the drive and control technology creates momentum for new investments in the market. Connectivity capabilities will become increasingly important in all drive and control technologies in order to boost productivity, flexibility and the ease of use.

Moreover, it is also important to train talent in such new trends and technologies. This can be done by creating customised training programs and academies in drive and control technologies. We have opened such academies in collaboration with technical universities in various states. In Ahmedabad, recently it was opened in collaboration with Gujarat Technical University. The purpose is to impart hands on training in the field of automation technologies for engineering students. This center is also unique as the hardware used in the training kits is Industry 4.0 competent and will give firsthand experience for the faculty and students.

Germany is one of India's most important trade partners. What are the differences and similarities between Indian and German manufacturing industries?

India's confident, innovative and fresh presence in the global economy is positioning itself as an up-and-coming industrial nation. India and Germany could play the role of a partner in modernising and transforming its dynamic economy. The combination of Indian IT expertise with German engineering strength would be mutually beneficial in the light of most recent developments like Industry 4.0.

Germany is aggressive in adopting and inventing state-of-the-art technology and the Indian consumer market is highly attractive globally. If both countries are able to integrate the supply from Germany and demand from India, the two nations can really benefit. India could also take advantage of the German system for vocational training. The Bosch Vocational Center in Bangalore has been an educational success story for more than 50 years now.

What are your growth plans in India? Are you looking at exports opportunity from India?

Providing one-stop solutions in drive and control technologies, Rexroth has periodically expanded its product portfolio, which has resulted in opening up new opportunities for the company. The company relentlessly works towards serving new segments by providing complete solutions to the customers. All of the company’s future plans are guided by its goal to emerge as a leader in drive and control solutions. We are making efforts in the direction of addressing the evolving needs of our existing customers while attracting more customers.

Related Stories

Hannover Messe 2025 presents battery cell and pack production for EVs

Electric mobility is seen as a key technology for long-term emission reductions – and consequently for a more sustainable future.

Read more

India presents a huge opportunity for HIWIN: Simon Liao

In this interview, Simon Liao, Deputy GM, 2nd Business Dept, HIWIN Technologies, highlights on emerging trends in India with customers demanding highly efficient, green technologies.

Read more

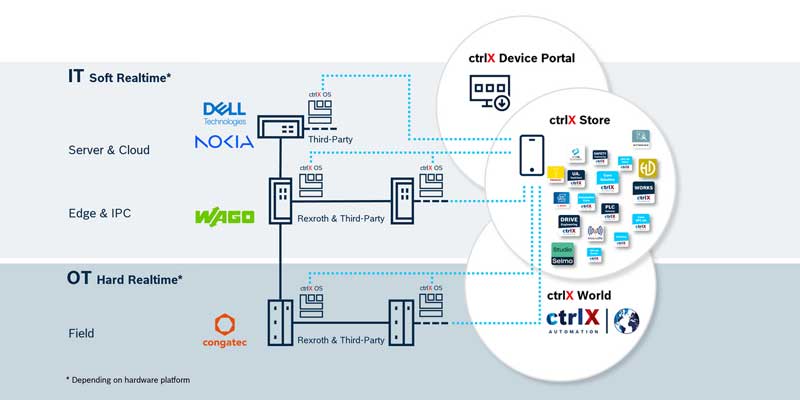

Bosch Rexroth and congatec open up new possibilities with ctrlX OS

Operating system ctrlX OS is now in embedded and edge computing products from congatec; users gain access to the entire ctrlX OS ecosystem

Read moreRelated Products

Premium Quality Reduced Head

Advance Hydrau Components Pvt Ltd offers an array of rivet nut, reduced head.

Blended Learning

Eduquestindia Institute Pvt Ltd offers Blended Learning. There is often a debate around the thought as to which is a better approach to training and development for corporates. On the one hand, the Read more

Rapid Authoring

Eduquestindia Institute Pvt Ltd offers Rapid Authoring. The business environment in which the modern day corporates operate is quite intriguing. An increased competition over time has brought in ad Read more