Schedule a Call Back

Vedanta Aluminium patents innovative breakthrough in bauxite refining process

Industry News

Industry News- Nov 07,23

Vedanta Aluminium, the largest aluminium producer in India, has announced the development of a groundbreaking process to significantly reduce the generation of bauxite residue, commonly known as red mud in the alumina refining process. The process reduces bauxite residue by a remarkable 30% by eliminating iron values while simultaneously recovering a higher alumina yield, reducing the total organic content from bauxite during the alumina refining. The process significantly enhances resource efficiency and curbs energy consumption during refining. The research project was led by the company?s Research and Development (R&D) department in collaboration with the Department of Metallurgical and Materials Engineering, Indian Institute of Technology Kharagpur (IIT KGP), with special support from the Lanjigarh, Odisha unit, home to Vedanta?s world-class alumina refinery. This cutting-edge development will enhance the company?s operational excellence and have a sustainable impact on the global aluminium industry.

Bauxite is the primary ore for aluminium, and it undergoes an intermediate refining stage, known as the Bayer process, to produce alumina, which is then subjected to electrolysis to produce aluminium. This refining process generates bauxite residue as a by-product. To produce 1 kg of aluminium, it requires 2 kg of alumina, which consumes 6 kg of bauxite, leaving behind 4 kg of bauxite residue. Managing this voluminous by-product sustainably has been a long-standing industry challenge. Vedanta Aluminium is actively engaged in minimising bauxite residue and exploring avenues to extract value from it. The company has developed a revolutionary process, which has been successfully validated in the laboratory and patented. Presently, the company is focusing on establishing a pilot plant to implement and assess the process, along with determining its potential advantages.

On the breakthrough, GG Pal, Dy. CEO ? Alumina Business, Vedanta Ltd, said, ?At Vedanta Aluminium, operational efficiency is of paramount importance for us in achieving sustainability. Toward this goal, we are aggressively focusing on our in-house R&D initiatives to drive tech-led innovative solutions to address existing industry problems.?

Sharing his thoughts on the development, Dr Amit Chatterjee, Chief Research & Development Officer, Aluminium Business, Vedanta, said, ?We look forward to implementing our groundbreaking process in bauxite residue management in our refinery operations. This is a significant milestone that will offer a pathway to enhanced resource efficiency and energy conservation and contribute towards reshaping the global aluminium industry.?

Dr Chenna Rao Borra, Assistant Professor, Department of Metallurgical and Materials Engineering, IIT Kharagpur said, ?Vedanta Aluminium?s dedication to R&D for sustainability goals is truly inspiring. The reduction of bauxite residue has been one of the key challenges for the aluminium industry, requiring significant technological advancements. The process, developed through the collaborative efforts of IIT Kharagpur and the company, will not only significantly improve bauxite residue management but also contribute to reducing the carbon footprint in the process.?

Related Stories

Avaada, GRIDCO and IIT-Bhubaneswar to Set Up Green Hydrogen CoE in Odisha

Avaada, GRIDCO and IIT-Bhubaneswar join forces to develop a Green Hydrogen Centre of Excellence in Odisha to drive advanced research and next-generation clean energy innovation.

Read more

Jindal Stainless Expands Slag Processing Capacity with USD 150 Million Investment

This initiative forms an integral part of Jindal Stainless’ long-term Environmental, Social and Governance (ESG) goals and its commitment to achieve Net Zero by 2050.

Read more

HCC Secures Rs 2,040 Mn Deal for Fabrication in Hindalco’s Odisha Expansion

HCC’s advanced fabrication expertise and execution capabilities will be crucial in delivering this large-scale industrial project to international standards.

Read moreRelated Products

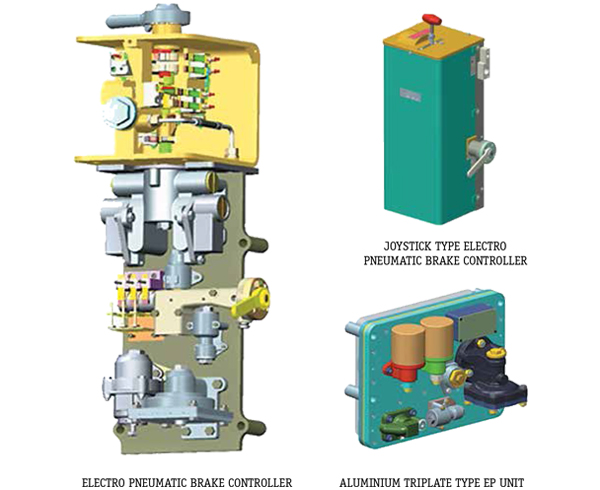

Electro - Pneumatic Brake System for Emu

Escorts Kubota Limited offers a wide range of electro - pneumatic brake system for EMU.

Indef Powered Crane Kit

Hercules Hoists Ltd offers a wide range of Indef powered crane kit.

Jib Crane

DC Hoist & Instruments Pvt Ltd offers a wide range of Jib crane.