Schedule a Call Back

HMS Networks' reveals growth in industrial network market

Articles

Articles- Jun 20,24

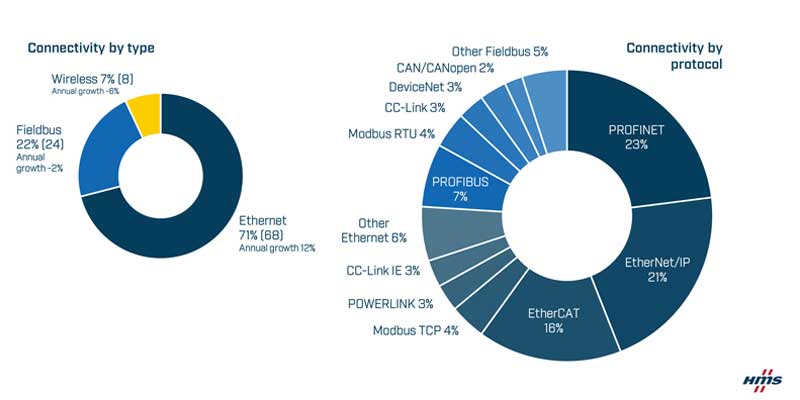

In the 2024 study, HMS concludes that the industrial network market continues to grow, with total market growth in 2024 expected to be +7%, confirming the continued importance of network connectivity in factories, says Magnus Jansson, Product Marketing Director, HMS Networks. Each year, HMS Networks presents their analysis of the industrial network market, focusing on newly installed nodes within factory automation globally. As an independent supplier of solutions within industrial ICT (Information and Communication Technology), HMS has substantial insight into the industrial network market. The 2024 study includes estimated market shares and growth rates for fieldbuses, industrial ethernet, and wireless technologies. Steady growth Growing by 12%, industrial ethernet accelerates its growth and continues to capture market share. Industrial ethernet now accounts for 71% of the global market for newly installed nodes in factory automation (compared to 68% last year). Profinet is the largest protocol, with a market share of 23%, surpassing EtherNet/IP, which accounts for 21% of new nodes. The popularity of EtherCAT remains strong and is now securely in third place with a 16% market share. Fieldbuses expected to decline Traditional serial fieldbus installations continue to lose momentum. While fieldbus installations still constitute a significant portion of new nodes added, annual growth is expected to drop by -2% in 2024. Profibus leads the fieldbus rankings with a 7% market share, followed by an even distribution among other well-known fieldbus protocols. Together, fieldbuses account for 22% of the market in 2024. Despite the decline in new fieldbus nodes, many devices, machines, and factories will continue to rely on these well-functioning and proven fieldbuses for years to come. Steady presence Wireless technologies have seen steady growth in recent years, although the pace of growth is now reported to have slightly decreased. Wireless solutions still comprise a robust 7% of the total share by type. The market continues to introduce more products with support for industrial wireless, and acceptance of wireless solutions in factory settings is on the rise. Typical use cases include cable replacement applications, wireless machine access, and connectivity to mobile industrial equipment. Conclusion Industrial networking is now key for productivity and sustainability in manufacturing. Connectivity is now a standard in factory automation, with industrial ethernet leading the way. However, as we look ahead, we anticipate a dynamic landscape with emerging trends and technologies. While industrial ethernet currently dominates the sector, we will witness exciting changes and innovations that will shape the future of industrial networking.

Related Stories

Industrial Ethernet now powers 76% of factory automation nodes: HMS Networks

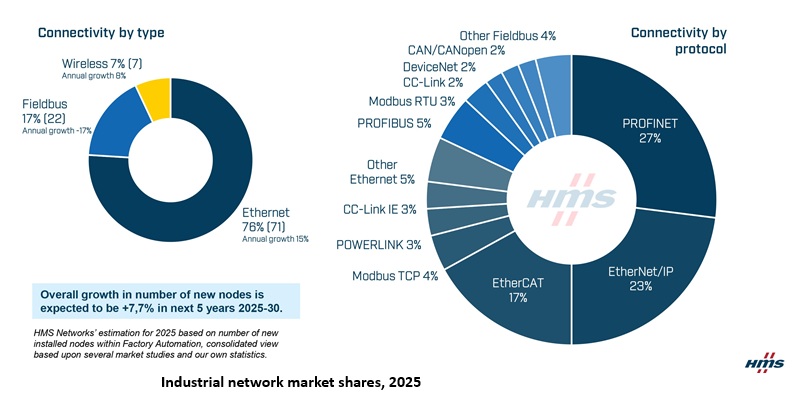

HMS Networks’ 2025 report shows Industrial Ethernet now powers 76 per cent of new factory automation nodes, as fieldbus tech declines. Despite a short-term slowdown, long-term market growth is for..

Read more

LAPP launches first bio-cable in series production for sustainable connectivity

LAPP is now working intensively on the sustainable optimisation of sheath materials and is further promoting the use of bio-based plastics.

Read more

HMS Networks' reveals growth in industrial network market

Wireless solutions still comprise a robust 7% of the total share by type.

Read moreRelated Products

Heat Exchanger Scale Removal Compound -hesr-300

Dna of All Information

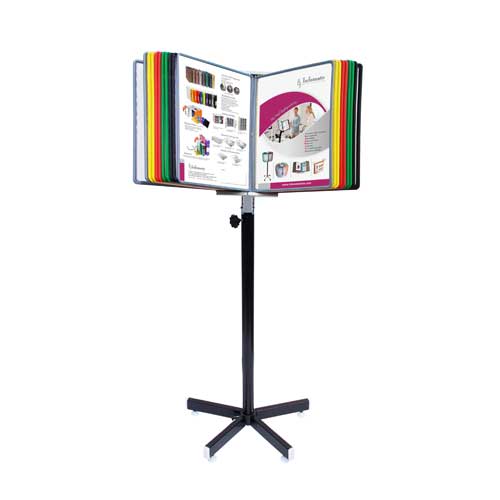

Roto Leaner Technology Pvt Ltd manufactures a complete range of display solutions.

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy