Schedule a Call Back

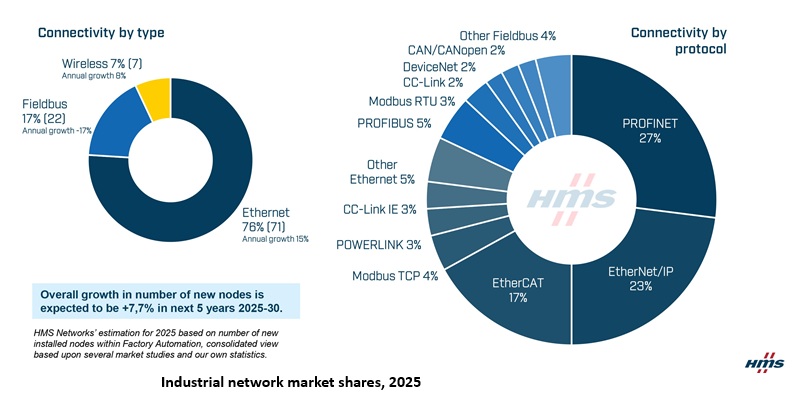

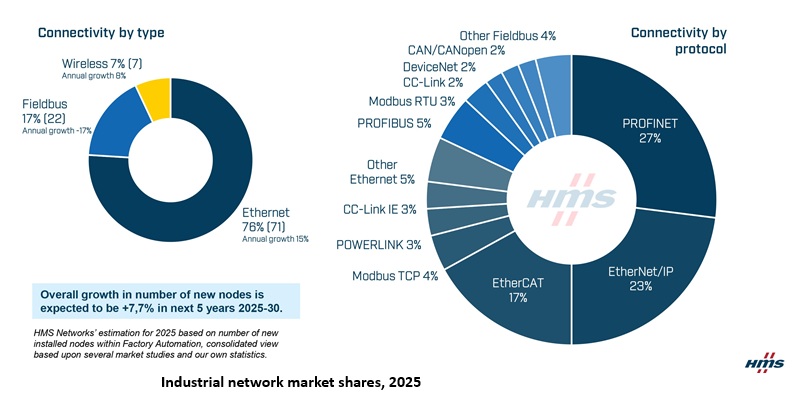

Industrial Ethernet now powers 76% of factory automation nodes: HMS Networks

Industry News

Industry News- Jun 04,25

- PROFINET leads at 27%, rising from 23 per cent last year

- EtherNet/IP holds 23 per cent

- EtherCAT strengthens to 17 per cent

- Modbus TCP remains at 4 per cent

- Other Ethernet standards, such as POWERLINK and CC-Link IE, maintain niche yet stable positions

- PROFIBUS leads but drops to 5 per cent

- DeviceNet, CC-Link, and Modbus RTU each see a 1-point decline

- CAN/CANopen holds at 2 per cent

- Other legacy protocols collectively account for 4 per cent

- Europe: Strong growth in PROFINET and EtherCAT, with rising interest in APL (Advanced Physical Layer) and Single Pair Ethernet (SPE) for enhanced process automation.

- North America: EtherNet/IP leads. Adoption of IO-Link, APL, and SPE is gaining pace as smart device integration intensifies.

- Asia: Both PROFINET and EtherCAT are expanding in China, while CC-Link IE maintains a strong foothold, being the first to adopt TSN (Time Sensitive Networking).

Related Stories

Igus expands D1 motor control with certified PROFINET

PROFINET/PROFIdrive integration and fast cycle times of the D1 allow for reliable and flexible control systems for motors in various automation applications.

Read more

Sixth Edition of Mitsubishi Electric Cup for automation innovation launched

This national-level competition, hosted by Mitsubishi Electric India, challenges engineering and technical students to apply industrial automation technologies to solve real-world problems.

Read more

Industrial Ethernet now powers 76% of factory automation nodes: HMS Networks

HMS Networks’ 2025 report shows Industrial Ethernet now powers 76 per cent of new factory automation nodes, as fieldbus tech declines. Despite a short-term slowdown, long-term market growth is for..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy