Schedule a Call Back

Global hydraulics market thrusts upward

Articles

Articles- Mar 24,25

Infrastructure boom

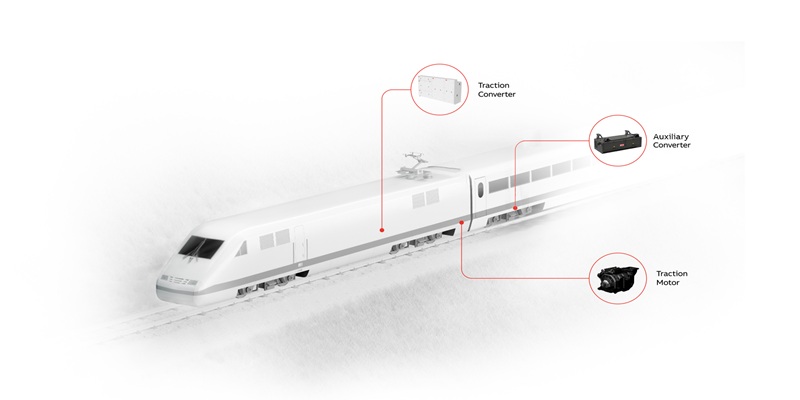

Infrastructure development remains one of the most significant growth drivers for the hydraulics market. Governments and private sectors worldwide are investing heavily in urbanisation, smart cities, and transportation networks, increasing the demand for heavy-duty hydraulic machinery. The UK government, for instance, increased its infrastructure investment by 9.6% in 2022, reaching approximately $32.4 billion. Such projects necessitate advanced hydraulic equipment for large-scale construction activities, reinforcing market growth. Countries such as China and India are also seeing a surge in hydraulic equipment demand due to large-scale road, rail, and urban development projects.

Related Stories

Fujiyama to Commission 1 GW Solar Cell Manufacturing Plant at Dadri

Fujiyama Power Systems has announced the commissioning of a 1 GW solar cell plant at Dadri, Uttar Pradesh, strengthening its integrated manufacturing capabilities and reducing reliance on imports.

Read more

Legrand Inaugurates One of Its Largest Global Manufacturing Facilities in Nashik

Group Legrand India has inaugurated a 30,000 sq m manufacturing facility in Nashik, reinforcing India’s role as a global manufacturing and export hub.

Read more

Neolite ZKW Commissions New Automotive Lighting Plant in Pune

Neolite ZKW Lightings Limited has commissioned a new manufacturing and design facility in Pune to strengthen automotive lighting capabilities and support OEM customers across vehicle segments.

Read moreRelated Products

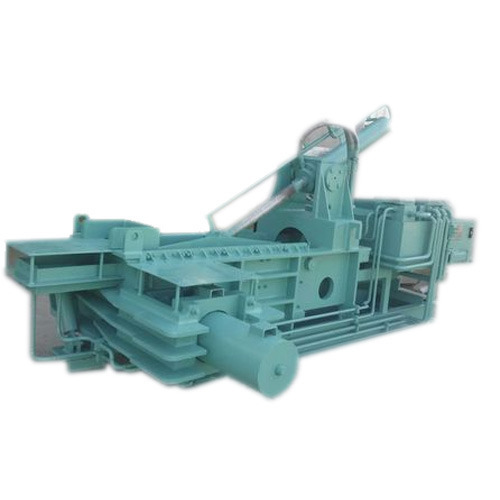

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more