Schedule a Call Back

Gleason to present latest technologies at JIMTOF 2022

Industry News

Industry News- Nov 03,22

At JIMTOF 2022, from November 8 to 13, Gleason to present the latest gear design, manufacturing and inspection systems in challenging times of transformation. Exhibits and live streams include KISSsoft’s design software release 2022, new gear chamfer cutting technologies, hard finishing of gears by super finish honing, combi honing and polish grinding, hobbing and power skiving on one flexible platform, revolutionary gear metrology systems with laser scanning, sub-micron inspection and in-process gear inspection with integrated gear noise analysis.

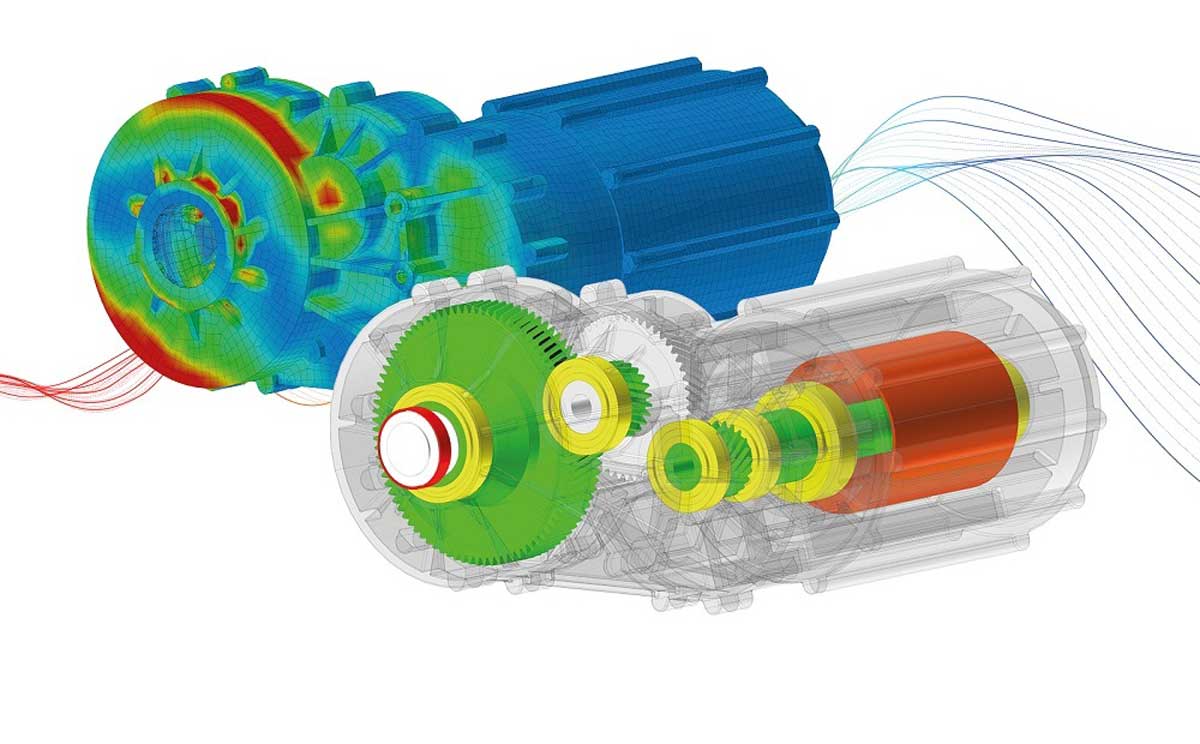

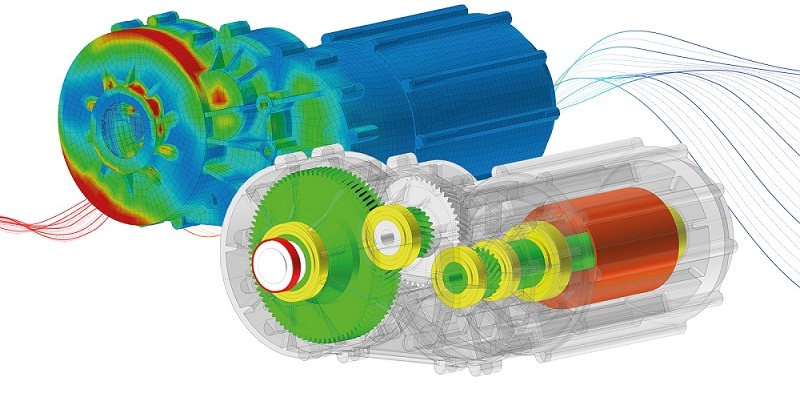

KISSsoft design and transmission software will present its latest 2022 release with a wealth of new features and functionalities including smart loop feedback to production machinery for fast and efficient design adjustments in the prototyping phase, integrating design into manufacturing and inspection processes.

Gleason’s 300GMSL Gear Metrology system features laser scanning for gear inspection at the speed of light, providing the data for unprecedented real-time analytics to speed up the development of complex gears, maximise efficiency, and minimise sound emissions in EV and other gearboxes.

The new 300GMS nano Gear Metrology System provides for gear inspection capability at submicron level, integrating highly sophisticated tools to analyse waviness for profile, lead and pitch, and to determine gear noise characteristics of e-drive gears.

Exhibits will be complemented by manufacturing and inspection demonstrations via live streams from global Gleason operations worldwide presenting new developments in hard power skiving, medium size bevel gear cutting, gear honing by Super Finishing for excellent surface finishes, threaded wheel grinding for gears with mirror-like surfaces and 100 per cent in-process gear inspection.

Gleason invites customers to the traditional Dr Stadtfeld Day at Tokyo Big Sight, Floor East 9F, Room 909, starting 10:00 AM JST Dr Stadtfeld will present the latest developments for the future of bevel gear manufacturing, including flexible cutting with Superi-Ac Ecoblade RT, psychoacoustic noise reduction with Microform, Coniflex Plus for strong and quiet e-drive differentials, bevel gear e-drive concepts and a brand-new process for fast cutting of differential gears.

The Gleason team is looking forward to meeting customers in person at JIMTOF at Tokyo International Exhibit Center in Tokyo, Japan at Booth E6007 in East Hall 6.

Gleason is a global leader in gear technology. Gleason’s "Total Gear Solutions" range from gear and transmission design software to the development and production of gear manufacturing machines and related accessories, gear metrology equipment and automation systems. Gleason products are used by customers in the automotive, commercial vehicle, aerospace, agricultural, mining, energy, construction, power tool, marine and many other industrial equipment markets. Gleason has manufacturing facilities in the U.S., Brazil, Germany, Switzerland, India, China and Japan, and operates sales and service offices in North and South America, Europe and Asia Pacific.

Related Stories

The Showstoppers at IMTEX 2023

With 991 exhibitors and more than 96,000 visitors from 23 countries, IMTEX 2023 was a showstopper for the manufacturing industry in India. Rakesh Rao lists here companies who displayed their cutting..

Read more

KISSsoft and RecurDyn hosts live session for e-drive design

Electric vehicles could represent up to 70 per cent of all cars by 2050. To ensure the acceptance of their vibrational and acoustical characteristics, profound NVH (noise, vibration, and harshness) ..

Read more

KISSsoft and RecurDyn hosts live session for e-drive design

The session presented a common and continuous solution to design, analyse and optimise the NVH (noise, vibration, and harshness) behaviour of a gearbox used in an e-drive system.

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.