Schedule a Call Back

ABB India doubles its Gas Insulated Switchgear (GIS) capacity with a new factory

Industry News

Industry News- Mar 03,23

Related Stories

Let’s decarbonise: A turning point for mining in Asia

Sustainability uncertainties in mining are well known. Encouragingly, mining is already undergoing a notable transformation—one that brings with it great potential to build a more resilient and su..

Read more

SAIL partners ABB India to drive digital transformation in steel manufacturing

Two companies will explore developments for Rourkela Steel Plant to improve productivity and efficiency of operations. Data-driven models will be used to assess opportunities for optimising ironmaki..

Read more

ABB India launches AI-powered startup challenge in smart drives

The last date to submit applications is April 29, 2025.

Read moreRelated Products

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.

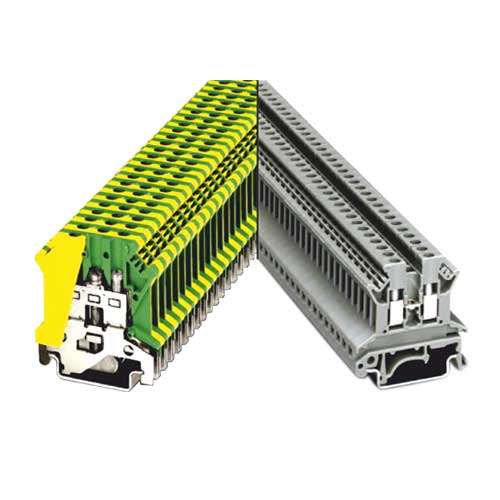

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.