Schedule a Call Back

One Cable Automation opens door to machines without control cabinets

Industry News

Industry News- May 09,19

Related Stories

Beckhoff presents automation solutions for machine tool industry

Beckhoff offers a complete range of PC-based control and automation for metal forming, metal cutting and machine tools/SPMs. At IMTEX Forming 2024, company is all set with its offerings to customers..

Read more

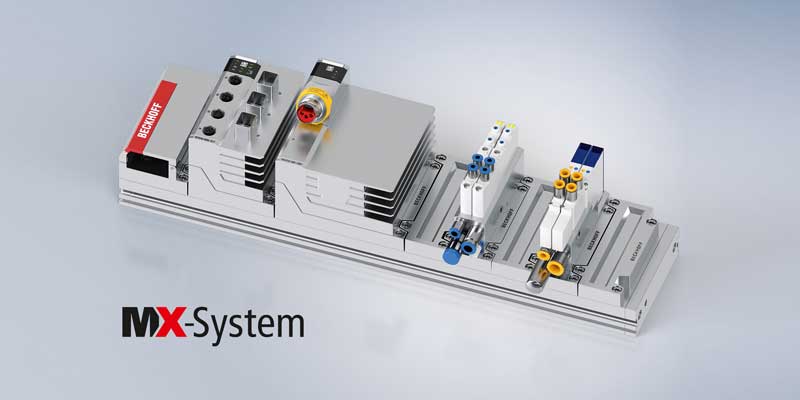

Beckhoff extends MX-System with pneumatic modules

The control cabinet-free automation MX-System launched by Beckhoff in 2021 is now included with pneumatic valves. The developed two socket modules – MO2414 for Festo and MO2424 for SMC are with th..

Read more

Energy sector is Beckhoff’s biggest market in India

In this interview with Rakesh Rao at Hannover Messe 2023, Marcel Meier, Area Sales Manager International Sales, Beckhoff Automation GmbH & Co KG, discusses about the company’s vision and its strat..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy