Schedule a Call Back

EMAG to showcase solutions on Industry 4.0, electromobility & UMTI at EMO 2019

Industry News

Industry News- Aug 20,19

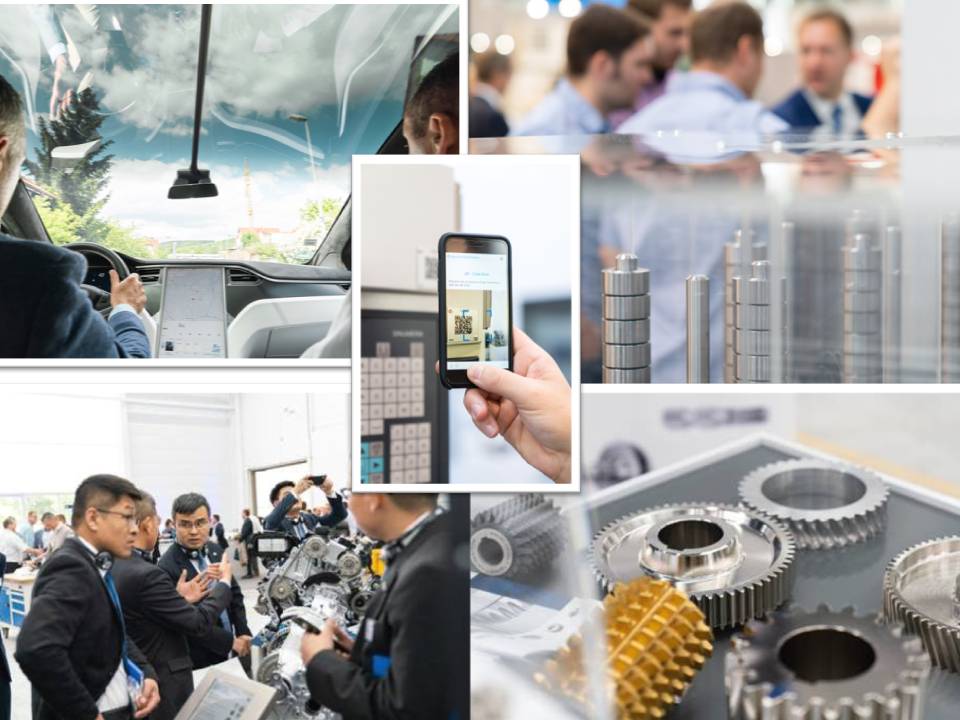

In a bid to solve difficulties in faced by the industry, EMAG Group will feature a host of solutions targeted on ‘the future of the automotive industry’ as discussed in the EMAG 2019 Technology Forum in May this year. The company claims that the solution showcase will be a sequel to the Technology Forum hosted by the company.

The technology forum provided a comprehensive outlook on what suppliers and manufacturers have to prepare for in the coming decade. As per the press release issued by EMAG Group’s Technology Forum, “Research experts have reported on how electromobility and digitalisation will change mobility. At the same time, visitors were able to catch up on the latest manufacturing systems and machines at numerous thematic booths. According to the visitor survey, this concept really hit the mark. That is why there will be a sequel to this successful concept at the EMO trade fair in Hanover, Germany.”

Problems solving requires right tools and the corresponding know-how. Both go hand-in-hand with each other. Thus, EMAG booth at the EMO trade fair will be featuring the latest machine tools and automation solutions to celebrate their world premiere at the EMO. Regular updates will be published on the EMAG Group’s blog https://www.emag.com/blog/en in the coming weeks.

The know-how required to combine these machines and the technologies of the group’s companies into efficient manufacturing solutions, in the ‘themed areas,’ will be entirely dedicated to the production of specific groups of components. Visitors will get answers to their questions and they can also find the matching manufacturing solution. The offer ranges from single-machine solutions to fully automatic manufacturing lines that are delivered to customers turnkey ready for operation, including the entire development process.

One of the significant topics at the EMAG Group’s technology forum was electromobility and its implications for manufacturers and suppliers. Yes, changes are about to come, but at a much slower pace than expected. So, should we carry on as usual? No, if ever, this is the right time to position yourself. Which components will be required in the future? What manufacturing solutions are available? What investments do I have to expect? EMO visitors will find answers to these questions at the EMAG Group’s booth. You will come across new components, things such as differentials or brake discs will still be required regardless of the drive technology implemented. For all these components and many more, EMAG will be showing the matching solutions and, beyond that, reveal major insights from the 2019 Technology Forum.

True to the EMO motto: Smart technologies driving tomorrow's production networking will be another major topic for the EMAG Group at the EMO. It will be considered from different perspectives. The ServicePlus app ensures optimal networking between customers and the EMAG service department. Simply scan a QR code on the machine using the app and you will be able to directly communicate with the service department, request a service callback or directly initiate a spare parts inquiry. The benefits are obvious: On the one hand, our service technicians immediately know which machine is concerned and its exact configuration. On the other hand, users automatically speak to the right contact. The entire communication of the EMAG ServicePlus app takes place on an EMAG-owned server and thus guarantees the highest security standards.

Ongoing developments of the EMAG Group’s industry 4.0 applications are intended to manage the networking between EMAG machines. In this context, EMAG will show among others how data can be visualised. Using a model, visitors will be able to gain their own impression of how the data flows. All you need to do is to visit the booth and experience it for yourself.

An entirely different type of networking, namely between 17 project partners and the German machine tool builders' association VDW has led to the development of UMTI (universal machine tool interface), which will be introduced for the first time at the EMO. A demonstration of the interface standard will be shown in hall 9 and professional visitors will be able to get first-hand information about the project. You can also experience how its implementation works at EMAG at the industry 4.0 thematic booth.

The EMAG Group will be showing a whole array of solutions for the most diverse applications in hall 17 at booth C 29. The corresponding processes stretch from raw parts all the way to final high-precision fine machining—a fact that not least owes to the group’s broad range of technologies. Whoever is searching for concrete solutions will not get around visiting the EMAG Group’s booth at the EMO.

Related Stories

India is at a pivotal ‘Make in India’ inflection point: Manoj Patil

In this interview, Manoj Patil, Promoter and Managing Director, Patil Automation Limited, outlines its growth journey, capacity expansion, acquisitions, design-led approach, market challenges, and t..

Read more

Manufacturing Excellence in the Age of Integrated Automation and Industry 4.0

Manufacturing leadership is shifting from scale-driven efficiency to integrated, data-led systems that deliver resilience, sustainability and enterprise-wide performance through Industry 4.0 and aut..

Read more

Resilience in Metal: Forging the Make in India Future in a VUCA World

The article examines how India’s stainless steel sector can turn global volatility, CBAM and supply risks into strategic advantages through sustainability, quality enforcement and digital transfor..

Read moreRelated Products

Fasteners for Automobiles

Bagadia Industrial Fasteners offers a wide range of fasteners for automobiles.

Automotive Shock Absorbers - Auto Parts

TMA International Private Ltd. has export comprehensive range of shock absorbers.

Factory Automation Service

Frontline Technologies offered factory automation services.