Schedule a Call Back

Schmersal launches Electromechanical Solenoid Interlock 2.0

Communication Feature

Communication Feature- Apr 08,25

The task is clear:

solenoid interlocks are designed keep a guard door locked until a hazardous

overrun movement has come to a halt. Varied types of solenoid interlock have

this same basic principle in common. Manufacturers, like the Schmersal Group, have

more than just one series in their range – Schmersal has eight, in fact, each

with its own specific application profile (Figure 1).

Slimline design, good integration

The AZM150 series, one of

the newer types of solenoid interlock, is now available as a fundamentally

overhauled version and is aimed at users looking for a more slimline design

(Figure 2). It is suitable for mounting on standard 40 mm profile systems as

well as for mounting on conventional machinery enclosures, particularly those

with smaller guard doors. The AZM150 has only a small installation footprint

and can be easily integrated into the surrounding structure, thus having no

impact on machine loading and unloading. The locking force of 1,500N is also

perfectly adequate for common applications in mechanical engineering.

When costs play a role

Another criterion is the

desire for a cost-effective solution for a maximum safety level of PL d/Cat 3.

This level is achieved just as efficiently with the electromechanical AZM150 as

excellent tamper protection with coding level ‘High’. At this level, the

designer or machinery builder benefits from needing to implement fewer additional

measures in accordance with ISO 14119 to guard against tampering, such as inaccessible

or concealed mounting. This makes the design ‘leaner’ and more straightforward indirectly

being cost-effective.

Wide range of uses

A notable feature of the AZM150 is its actuator head, which can be rotated by 4x 90°, rather than being bolted in place, and locked easily by simply putting the enclosure cover in place. The version with integrated eight-pin M12 metal connector also enables rapid connection to the safety logic and connection to the failsafe Schmersal ‘Safety Fieldbox’. This makes this series extremely versatile. The combination option with different actuators for different installation situations is also a perfect match. The range includes straight and angled actuators for sliding doors, as well as an adjustable movable actuator for revolving doors. The extensive range of accessories includes; mounting plates, locking tongs and an emergency release (from the outside) as well as auxiliary release and escape release (from the hazard zone) help to ensure optimal customisation to the individual application. In the event of installation on security fences or heavy doors, the corresponding DHS150 door bolt can also be used (Figure 3).

Less can be more

If the features mentioned

here fit the profile (spatially and in the figurative sense), the user has no need

for an electronic solenoid interlock and would be better off using the electromechanical

AZM150. Exclusion criteria are both a required performance level of PL e/Cat 4 and

the desire for a connection to safety-related bus systems (ASi Safety at Work),

so anyone who needs these features should consider the range of electronic solenoid

interlocks, such as the AZM40 (Figure 4). As the world’s smallest electronic

solenoid interlock, it is even more compact, but has a higher price due to the

integrated electronics.

Simple actuating via standstill monitor

Each interlock has an

evaluation unit and standstill monitors, which issue the signal to unlock as

needed, have become a firmly established component for this. An appealing model

that fits well with the AZM150 is the SSW 303HV, a universal failsafe

standstill monitor that works without sensors (Figure 5). This means that the

machine designer of the machine need not intervene in the surrounding construction.

The safety module is connected directly to a three-phase motor and measures the

frequency of the induced voltage, at rated motor voltages of up to 690V. The

enable fields close as soon as the motor comes to a halt.

Not only for occupational safety

Previous applications of

the AZM150 are wide and varied and include packaging machinery with up to 20

guard doors. Here, users benefit most particularly from the more attractive costs

when compared to electronic solenoid interlocks and from the flexibility offered

by the toolless rotating actuator head (Figure 6). For some applications, the

reason for using the AZM150 is not the safety of machinery, but process safety,

which is typical for solenoid interlocks in general. This means that no hazardous

overrun movement is anticipated. Instead, the goal is to prevent the operator from

interrupting the process by opening the guard door, a process that can only

then be restarted through complex measures (resetting to zero, calibration,

releasing production goods due to abrupt halts, etc.). For situations like

these, the AZM150 is appropriate, which operates according to the open-circuit

current principle instead of the closed-circuit current principle.

Improvements in detail

Schmersal is currently in

the process of launching an overhauled version of the AZM150, which differs

from its predecessor in terms of the many design improvements. An expansion of

the range and accessories for this universal electromechanical solenoid interlock

is planned for the near future.

-------------------------------------------------------------

About the author:

Marco Kiederle, Product

Manager-Safety Technology, Schmersal

Group, Wuppertal.

Related Stories

Indian manufacturing sector: Negotiating its way in a less VUCA world

India’s manufacturing sector is evolving through policy support, technology adoption and sectoral growth, though challenges in R&D and skilling remain, writes Prof R Jayaraman, Head, Capstone Proj..

Read more

Manufacturing Strength Behind India’s Self-reliance and Global Positioning

India’s manufacturing sector is evolving from domestic self-reliance to global leadership, navigating a VUCA environment through strategic policy, capability building and infrastructure-led execut..

Read more

India’s Manufacturing Reset in an Uncertain World

Global manufacturing is being reshaped by volatility and disruption. This release outlines how India is strengthening depth, resilience and capability to emerge as a long-term manufacturing partner,..

Read moreRelated Products

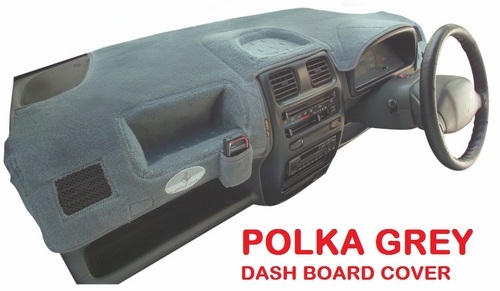

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.