Schedule a Call Back

INOX handpieces for Flexible shaft machines by SUHNER

Industry News

Industry News- Sep 27,17

Nowadays, more and more products are being manufactured from stainless steel and higher and higher requirements are being placed on the surface finish of these products. In the process, a problem has appeared that does not seem to be spectacular at first glance, but ultimately causes high costs: extraneous rust. Preventing tools from coming into the surfaces of usually very expensive parts during grinding is extremely difficult. Depending on the material of the tool, minuscule particles remain on the surface even in case of only brief contact. These particles become visible as extraneous rust over time.

To prevent this problem, a careful and therefore timely procedure is required. The universal SUHNER machines with a flexible shaft are the grinding technology of choice for professional applications. They offer versatility, performance and flexibility.

SUHNER has now developed a series of new handpieces for this all-rounder. They bear the additional designation 'INOX' and put an end to the problem of extraneous rust. The series comprises four basic models plus international variants, of which each is almost completely manufactured of stainless steel – from the external jacket to the clamping nut. In practice, this means: no contamination with rusting particles, the greatest possible protection of the workpieces and a clear reduction of costs . The structural design with dimensions, weight, speed ranges, and so on remains identical. The new handpieces thus fit the existing machines.

To protect the ball bearing and dampen vibrations, the handpieces have an elastic bearing. This makes machining with carbide cutters agreeable and protects the tools, while guaranteeing true running and a long service life. The handle sleeve is uncoupled from the working spindle. Air chambers in the bearing have an heat-insulating effect. During vibration measurements with carbide cutters, a 50% reduction was measured in comparison with previous handpieces. For a quick and easy change, the new handpieces are equipped with an additional mounting aid. The chuck diameters amount to 6, 8 and 12 mm with corresponding variants for the international market.

The handle sleeves have a cylindrical shape for safe clamping in chucks, e.g. for the attachment of safety devices or customer-specific adaptations. The external diameters are as follows: 18.5, 25 and 32 mm. SUHNER also provides all flexible shafts with stainless hose couplings that fit all handpieces in the standard design. This combination guarantees the long service life of both devices. The new, straight handpieces have been specifically developed for the processors of INOX materials in the area of surface processing or refinement. They are used in container construction for the pharmaceutical and food sectors, the construction of large kitchen furniture, the metal construction of stainless steel doors and windows, and railing construction and wherever a lasting, fine finish is decisive in stainless steel processing.

Related Stories

Suhner introduces EFC-02, electric force compliance system

Suhner provides metal processing solutions to for various industries. It is expanding its suite of robotic grinding accessories and tools with the fully electric EFC-02.

Read more

The Showstoppers at IMTEX 2023

With 991 exhibitors and more than 96,000 visitors from 23 countries, IMTEX 2023 was a showstopper for the manufacturing industry in India. Rakesh Rao lists here companies who displayed their cutting..

Read more

Sundram Fasteners bags $ 250 mn contract from global EV maker

SFL plans to invest Rs 200 crore to support the new orders under the six-year long purchase package involving the supply of input & stator shaft sub-assemblies and drive gear sub-assemblies.

Read moreRelated Products

Electric Brick Making Machine

Mortek Machinery manufactures and supplies electric brick making machine.

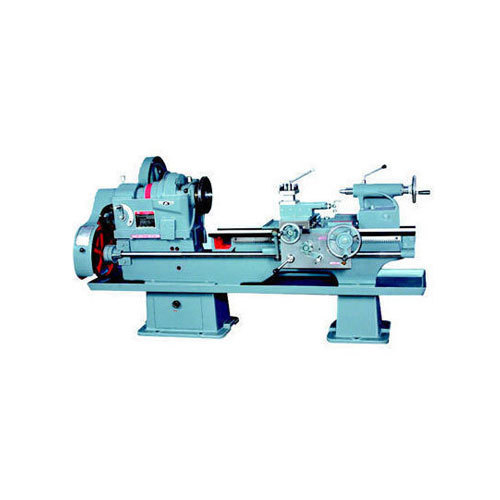

Lathe Machine

Atul Machine Tools is a manufacturer and importer of conventional lathe machine.

Turning Machines

D P Enterprises imports and trades the finest quality of CNC turning machines.