Schedule a Call Back

Lithium-ion battery charging the future green

Industry News

Industry News- Jul 29,24

Related Stories

Lithium-ion battery charging the future green

The surge in demand for lithium-ion batteries in India is primarily due to their widespread usage across various industrial sectors, including telecommunications, healthcare, and uninterruptible pow..

Read more

Park+ survey shows most Indian EV owners consider shifting to ICE vehicles

A significant 88% of respondents expressed concerns about charging anxiety, surpassing the traditional worry of range anxiety.

Read more

Park+ survey shows most Indian EV owners consider shifting to ICE vehicles

A significant 88% of respondents expressed concerns about charging anxiety, surpassing the traditional worry of range anxiety.

Read moreRelated Products

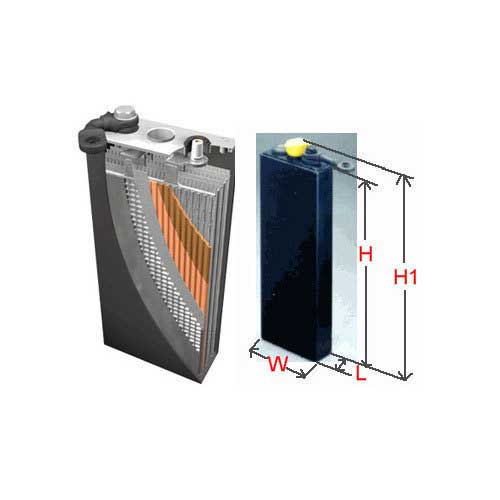

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more