Schedule a Call Back

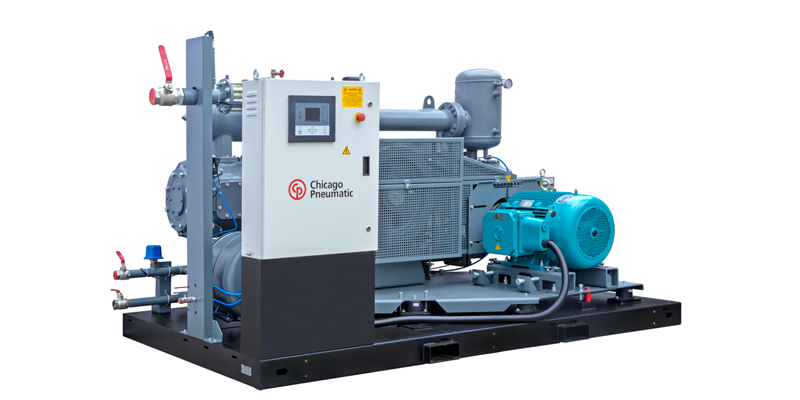

Top eight maintenance tips to extend the lifespan of reciprocating compressors

Articles

Articles- Nov 03,25

Related Stories

Top eight maintenance tips to extend the lifespan of reciprocating compressors

In this article, Siddhartha Guin, Business Line Manager (CTS), Chicago Pneumatic Compressors, India, shares essential maintenance practices to help extend the lifespan of these vital machines. From ..

Read more

Ingersoll Rand to roll out new products in India in coming months

The company has launched 2 compressors in India. The current and upcoming launches will primarily be from small-scale sector, automotive and light industry - catering to the needs of painting, fabri..

Read moreLumax Cornaglia opens R&D centre in Pune for auto components

The targeted product line for the R&D centre is air intake systems, urea tanks, other automotive tanks, CAC ducts and other blow moulded parts.

Read moreRelated Products

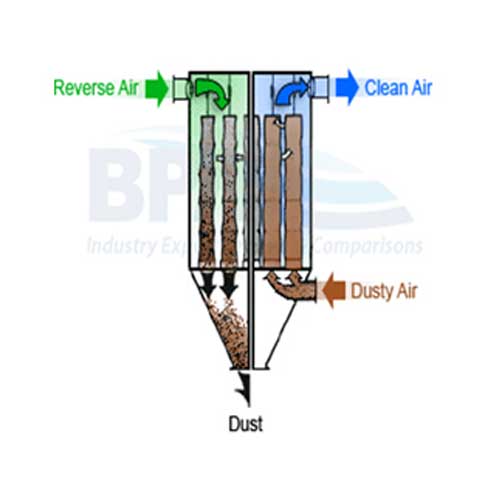

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series