Schedule a Call Back

Resilient supply chain: Delivering consistency and quality

Articles

Articles- Mar 13,24

- The capacity to recover quickly from difficulties;

- Toughness

- The ability of a substance or object to spring back into shape

- Elasticity: "nylon is excellent in wearability, abrasion resistance and resilience"

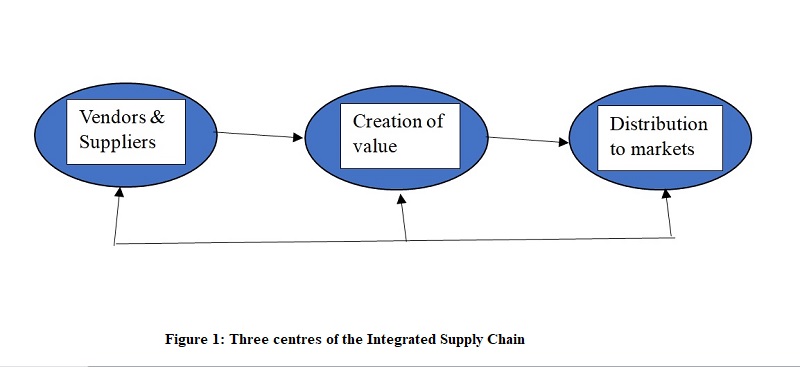

As was stated earlier, resilience is an integration concept rather than a problem- solving concept. Let us illustrate once again with examples. Let us say that the back-end is disrupted, resulting in shortage of supplies of certain components and raw materials. Then, the instinctive response is to procure the same from elsewhere. This is OK as long as there are other suppliers. However, other responses possible are: produce some other products, procure substitute inputs for the same products, procure from stores to the extent possible by maintaining inventories.

For the first option, decisions need to be made in terms of finding appropriate substitute products to be produced, which has several implications, like informing the current customers of possible delays, informing others that their deliveries could be advanced, and so on. These activities can be done only if the concerned departments are fully connected and work in co-ordination. For the second option, other suppliers need to be informed of the urgent supply needs, and, for the third option, the company must work on well-designed inventory management principles and decision rules.

The difference is, to identify such suppliers, and, for this, the company’s design department should be assigned tasks. This is a new response, specifically to create resilience. The additional tasks will increase the work of the design department, as well as the materials department, who will have to identify suppliers for these substitute inputs. Such additional tasks will be positioned in departments in the central box. It is also possible that the product mix will be enhanced, with substitute products to be produced as and when required. In the front end, customers will have to be informed of such substitute products, and consent obtained. Since the customers will also like the possibility of continuous, uninterrupted supplies, they will also agree.

Similar examples can also be provided for the central box, which will lead to additional tasks in the back-end as well as in the front-end. Overall, it can be appreciated that the ISC view will lead to creation of genuine RSC rather than a patchwork, from-time-to-time approach. The non ISC view will lead to crisis management and seat-of-the-pants driving, with the concomitant inefficiencies and customer dissatisfaction, ultimately leading to loss of business. In the Part III, we will define the new ‘rules of engagement’ for creating ‘genuine’ RSC.

(This is the Second article of 3-Part series column)

About the author:

R Jayaraman is the Head, Capstone Projects, at Bhavan's S P Jain Institute of Management & Research (SPJIMR). He has worked in several capacities, including Tata Steel, for over 30 years. He has authored over 60 papers in academic and techno economic journals in India and abroad. Jayaraman is a qualified and trained Malcolm Baldrige and EFQM Business Model Lead Assessor.

Related Stories

The role of risk management in large projects

Risk is inseparable from project management, particularly in large and long-duration projects, where inadequate risk identification, ownership and follow-up often lead to cost and time overruns. Pra..

Read more

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read more

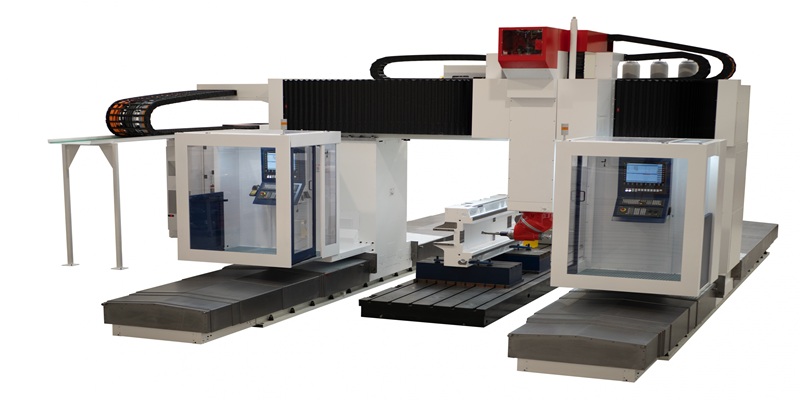

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read moreRelated Products

Fanless Industrial Pc for Smart Manufacturing

CONTEC Launches BX-M4600 Series - Fanless Industrial PC for Smart Manufacturing.