Schedule a Call Back

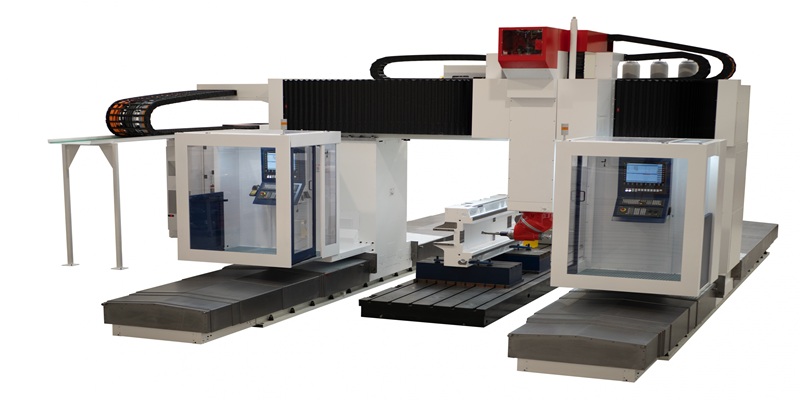

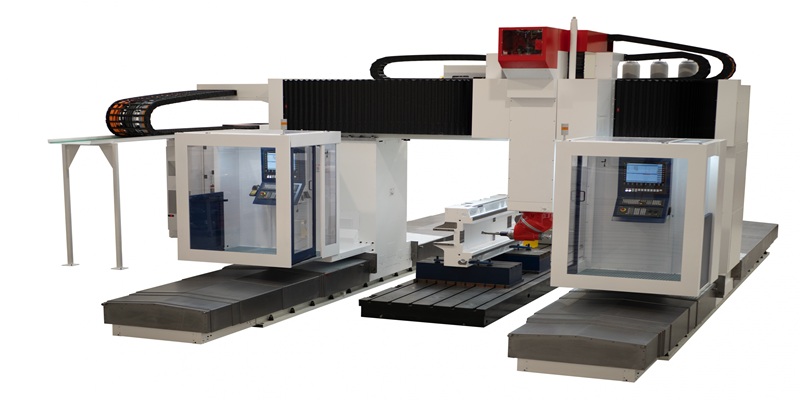

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Articles

Articles- Dec 17,25

When we talk about Italian manufacturing, adjectives such as

‘reliable’, for its attention to build quality, ‘robust’, linked to Italian

engineering and mechanical tradition, ‘versatile’, typical of Italian design

flexibility, ‘innovative’, for the all-Italian ability to combine tradition

with the search for technological solutions, and ‘excellent’, for its extreme

attention to detail and design. It is no coincidence that the Powermill G3 HPC3

was chosen by an Italian customer in the general engineering sector, because

this machine combines the robustness of large mechanical structures with the

innovation and versatility of the solutions offered by Mecof to meet the

customer's requirements for precision and reliability. For both of them, it is

important to achieve one goal: excellence.

Impressive dimensions,

millimetric precision

The machine described here is built to handle the accurate

machining of large workpieces: with strokes of 18 metres in X, 4.5 metres in Y

and 1.75 metres in Z, the Powermill G3 HPC3 offers a working capacity that

places it among the highest-performing solutions in its category.

The machine is equipped with a class II work surface in

accordance with DIN 876, 18 metres long and 3 metres wide, with a load capacity

of 15,000 kg/m square: figures that speak of extraordinary robustness.

The chain tool magazine with 80 positions and sliding

exchange arm, ISO 50 connection, completes the picture, reducing downtime and

ensuring maximum production continuity.

The versatility of

the dual-rotating head

At the heart of the machine's operational flexibility is the

universal dual-rotating head with automatic millesimal positioning, 38 kW and

615 Nm, capable of reaching 6,000 rpm with ISO 50 connection. The head is

designed for automatic changeover, an operation made even easier by the support

system, with a protective cradle equipped with positioning references that can

be quickly removed when not needed, optimising space.

Automation and

connectivity: Industry 4.0 on board the machine

Equipped with Heidenhain TNC 640 HSCI numerical control, the

same supplier also provides the options for the Industry 4.0 package, which

includes:

·

Heidenhain TNC Remo, for remote loading of

instructions and programmes,

·

Heidenhain DNC, which connects the machine to the

company's logistics systems,

·

CAPR, adaptive control that optimises machining

cycles in real time.

Control and

measurement always at hand

Precision is guaranteed by a complete package of control

tools: Renishaw RMP60 radio probe, kinematic measurement and laser system for

detecting tool length and diameter. All this helps to reduce errors and

increase the reliability of machining operations.

Smooth management and

chip evacuation

The customer raised the issue of proper chip evacuation, given

the machine's need to perform heavy-duty machining. The solution was quickly

found by integrating a dual-delivery cooling system, both external (6 bar, 28

l/min) and internal to the spindle (40 bar, 20 l/min).

This is supported by 2,000-litre filter and collection tanks

and a chip evacuation system with two ramp conveyors along the entire work

surface.

Safety and ergonomics

Safety does not necessarily mean that a machine must be

subject to strict construction and design rules; technology also comes to the

rescue in this area, giving the user full freedom to control and manage the

Powermill G3 HPC3 via the Heidenhain HR 550 FS wireless keypad and the

integrated video surveillance system with Bosch cameras and 19"

touchscreen monitors, which allows real-time monitoring of the work area, with

additional protection against chips and coolant.

The Powermill G3 HPC3 is not just a generously sized gantry

milling machine: it is a complete machine, designed to guarantee productivity,

precision and digital integration. For Italian and international general

engineering companies, it represents a strategic investment that combines

mechanical robustness, versatility and connective intelligence.

Related Stories

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read more

EMAG SU offers high-tech solutions for top component quality

With the G 160 for components up to module four with a maximum outside diameter of 160 mm, for example, EMAG SU has the fastest machine in the market.

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.