Schedule a Call Back

Looking beyond cobalt, Sandvik receives funds for research

Articles

Articles- Apr 03,23

Sandvik, a Swedish multinational engineering group providing products and solutions for mining and rock excavation, rock processing and metal cutting, invests heavily in innovation. With approximately 2,600 of the company’s 39,000 employees performing research at around 50 R&D centers worldwide. For years researchers in industry have been trying to find a solution for replacing or decreasing the use of cobalt in the company’s rock drill bits

A rock drill bit comes in various sizes, and a smaller model looks like a crown equipped with half a dozen spherical inserts. Since 1945, Sandvik has manufactured inserts of cemented carbide for rock drilling, where hard tungsten carbide is mixed with cobalt, which acts like a binding glue, creating an extremely hard composite that can drill through rock at an impressive speed. “We wanted to do research to investigate if it is possible to achieve a similar performance if we substituted cobalt with high-strength steel,” says Ida Borgh, Principal Engineer, Sandvik Mining and Construction Tools. At the beginning of 2022 there was a call for research projects on sustainable metals. This reflected the car industry’s shift to electric cars and the subsequent increased draw on the world’s supply of cobalt, which is used in car batteries as well as other applications. The time was ripe to apply for funding.

Sweden’s Innovation agency, VINNOVA, approved a SEK 7 million research project for three years in cooperation with KTH Royal Institute of Technology and Boliden Minerals, the Swedish multinational mining and metals company. “We’re very proud to have received the funding and for the collaboration with KTH, which means that we can accelerate our development with the help of the academy and their recently developed modeling methods,” says Susanne Norgren, Global Group Expert, Sandvik. “Also, having the end customer, Boliden, on board the project is of utmost importance when it comes to further designing the material.”

KTH will be responsible for materials modeling based on Sandvik requirements, using their newly developed method that can optimise new high-strength steel grades, which can potentially be used as a binder phase in cemented carbides.

Cobalt drillbits

“The method is unique and [on the] cutting edge,” says Borgh. “Combined with the material and application knowledge from industry partners this forms a strong partnership. Sandvik Mining and Rock Solutions will manufacture new cemented carbide grades based on the material modeling suggestions. We will test and analyse the new materials in our laboratory, which is designed for rock drilling applications. The drill bits will also be tested in one of Boliden’s mines. This means we have the whole value chain covered in the project.”

Important for sustainability

The project received strong support within the organisation. The R&D manager for cemented carbides, Annika Kaar, points out that this is an important area for the company’s sustainability work. “Sandvik has already decreased its demand for cobalt by recycling used drill bits,” she says. “If this research project is successful, it paves the way for future cobalt-free drill bits. This will have a positive impact from a sustainability perspective and will decrease vulnerability in the supply chain.”The researchers are optimistic, despite the immense challenge. High-strength steel may well become a base to replace cobalt. “We want to use a special effect to boost the performance of the steel,” Borgh says. “This is extremely difficult. No one has done anything like this before.” The project started in October 2022. “We will do field tests in 2025. It is exciting and we are eager to proceed. We love innovation,” says Kaar.

Related Stories

Seco redefines tool management with reconditioning and digital traceability

In addition to remanufacturing services, Seco operates a recycling program for carbide tools. When tools are too worn for remanufacturing, they are responsibly recycled into new products.

Read more

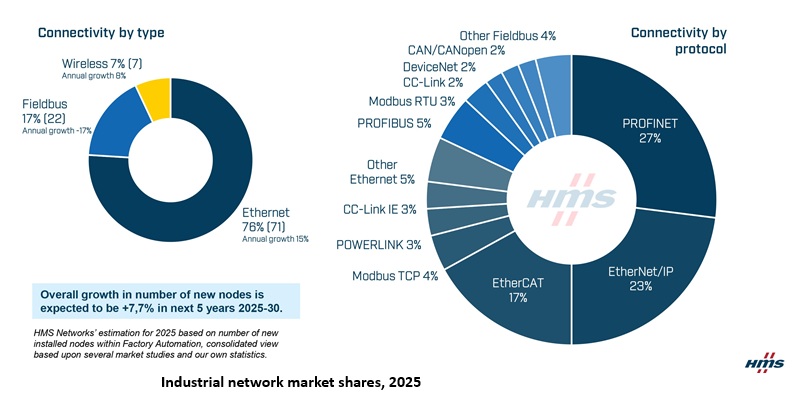

Industrial Ethernet now powers 76% of factory automation nodes: HMS Networks

HMS Networks’ 2025 report shows Industrial Ethernet now powers 76 per cent of new factory automation nodes, as fieldbus tech declines. Despite a short-term slowdown, long-term market growth is for..

Read more

India is a key strategic market for Hexagon: Jason Walker

In this interaction with Rakesh Rao, Jason Walker, VP, General Manufacturing Practice Lead, Hexagon, sheds light on the factories of the future and importance of India for Hexagon.

Read moreRelated Products

Auto Casting Components

Micro Melt offers a wide range of auto

parts casting components.

Robofinish Iron Casting Fettlingrcf

Grind Master Machines Pvt Ltd offers a wide range of robofinish iron casting fettling CF-HD series.

Casting Components

Micro Melt offers a wide range of auto parts casting components. Read more