Schedule a Call Back

INTEC 2019 ushering technological advancement in manufacturing

Articles

Articles- Jul 01,19

Related Stories

TSF Group showcases product line for global markets at IAA 2024

On display would be its extensive range of Braking solutions for the light commercial and heavy commercial vehicles including complete pneumatic braking systems.

Read more

GMCV 2030 gearing up manufacturing industry for growth

Finally unveiled at the conclave was the next year’s event ‘Small is Big: Conclave and Awardsâ€Â. It will be held on May 22, 2020. The sectors in focus for..

Read more

INTEC 2019 ushering technological advancement in manufacturing

With marketplace getting highly competitive, INTEC 2019 helped participants to gauge global technological trends and prepare for the future with new products and business strategy, says Rakesh Rao i..

Read moreRelated Products

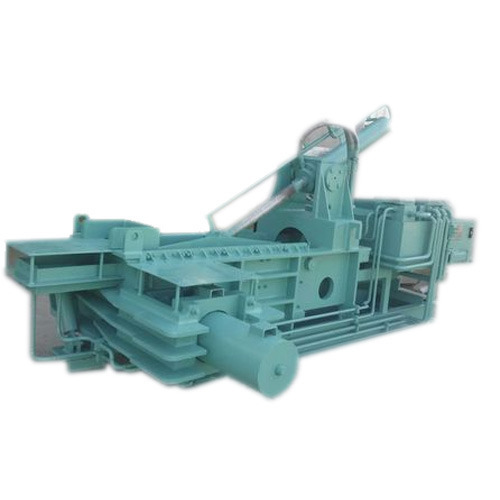

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more