Schedule a Call Back

Direct Warping Machines

Direct Warping Machines

Amritlakshmi Machine Works has been in the field of textile machinery manufacturing since the last 25-years and has been pioneers in the weaving preparatory field manufacturing high-speed direct warping machines and multicylinder sizing machines for spun and filament yarn, be it 100% cotton or its blends like PV, PC or viscose, jute, etc as well as 100% polyester or nylon or acrylic whether zero twisted, texturised or crimped, intermingled or rotoset, etc. Research & Development are inherent in every Amritlakshmi machine, and being tailor-made each machine is different from the other as it is manufactured to suit exactly a particular customer’s need & the required technology that goes along with it.

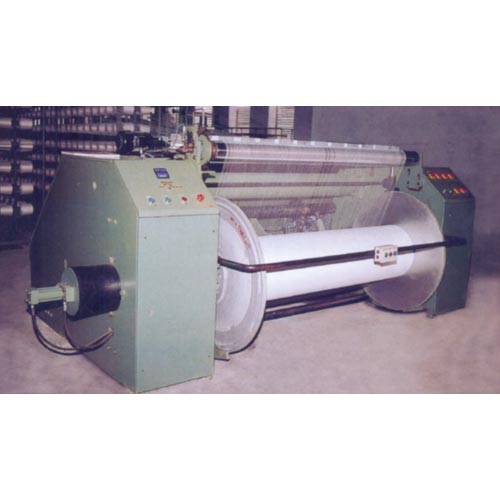

Direct warping system comprising creel and winding headstock

The latest in the range of high-speed WARPER HD series is a versatile product available for all kinds of yarn in varying widths from 1400 mm (55â€) to 2286 mm (90â€) or higher and flange diameter ranging from 800 mm (31.5â€) to 1400 mm (55â€). The warping process comprises a sturdy & well aligned creel of different capacities to accommodate the cones of varying diameters & weight as well as a winding headstock of different widths & flange diameters to wind the warp yarn on the dynamically balanced beam at high-speed with the help of unique “spindle driven system†coupled to powerful breaks. The Winding Headstock which is the “Control Centre†of the warping system is available in 3 varieties namely, Hydraulic Version, Pneumatic Version and the Drum Driven Version. In each case the available specifications are in the following range depending on the model:

- Beam Widths: 1400 mm to 2400 mm.

- Flange Diameters: 800 mm, 1000 mm and 1400 mm.

- Speed: 600 mpm, 1000 mpm or higher.

This Winding Headstock is a fully hydraulically operated auto version pre-assembled, synchronised and tested at the factory. The hydraulic system operates the press roll device, chucking and de-chucking device, doffing and donning of the beams, powerful braking of the beam as well as roller braking systems, which ensure the best performance resulting in high quality of warp beams. The Winding Headstock is also available in the pneumatic systems version, which is suitable for all varieties of yarn and has its advantages in lower cost for widths up to 1800 mm and flange diameter up to 800 mm.

Shore Hardness: The Shore Hardness of the Beam can be controlled by unique systems developed by Amritlakshmi, which gives a very fine control in the Hydraulic System to ensure uniformity of Hardness throughout the width with the help of the special Press Roll System.

Press Roll: Amritlakshmi has developed a special press rolls system, which is able to work with any kind of spun yarn and is available in variety of coating like Rubber FRP and hard chrome Plating thus ensuring a wound beam of desired hardness while keeping the press roll maintenance free for several years. Brakes: Large capacity disk brakes are employed at all strategic locations of the machine driving spindles, roller, etc which gives powerful and efficient dynamic braking to the machine drive and for hardness controls. The sturdy construction of the machines ensures jerk free operation. The ‘V’ Creel where the yarn travels “inside to outside†is a Tensionless Creel with individual Stop Motion and can be of fixed type or revolving frame types as required. It is popular abroad and recommended for yarn speeds more than 800 mpm to take advantage of the Air Tension due to the hairiness in the yarn. The ‘H’ Parallel Creel where the Yarn travel “inside to outside†can be of fixed type or with Revolving Frame and is now popular as it provides for a Adjustable Double Pole Tensioning Arrangement with Tensioner Disks where it is possible to adjust the tension being imparted to the yarn as required. There is provision to add weight washers over the tensioner disks to increase the Braking Tension. The yarn moves almost in a tensionless manner except the tension imparted by the angle of the Double Pole Tensioner and the disks with or without the weight washers are “Floating†when the warping machine is running at high speeds.

Truck type CREEL: Amritlakshmi also offers magazine truck type CREEL where pre-loaded trucks can be directly placed between the Creel sections on the track spare trucks can be loaded simultaneously. The system is very beneficial where the department width is limited and automatic pre-loading of the truck facilities are available in Cone Winding.

Special features of the CREEL

Balloon Breaker: An arrangement is provided which allows the unwinding balloon length to be controlled or broken into multiple balloons to limit the high unwinding tension and to prevent snarling the system is essential while working high twist yarn.

Travelling Blow (Optional): This Blower has necessary Suction and Blowing Hoses and Nozzles connected to the main blowing system, which is mounted on the creel and traverses to and from along the length. During this moment the system continuously blows air to clean the Tensioners, Stop Motion device (in case of individual devices) & the waste/dropping fallen on the floor in the predetermined range in the CREEL area is sucked into the system & collected in the canvas bags. The system is very helpful for working heavy, coarse and high density sorts at a super high-speed operation.

Product & Technology News

Products from Amritlakshmi Machine Works

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads