Schedule a Call Back

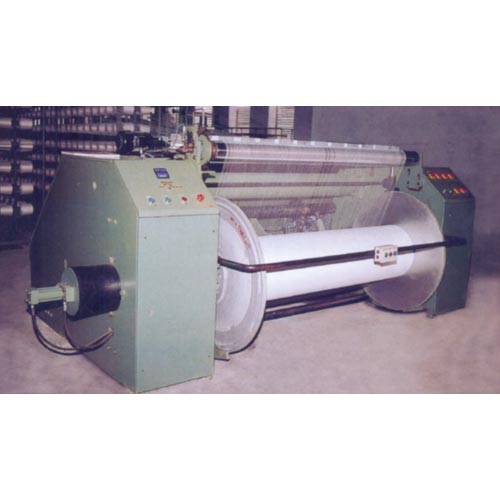

High-Speed Warpers

High-Speed Warpers

Amritlakshmi Machine Works, Mumbai offers the latest in the range of High-Speed Warper HD Series, which is a versatile product available for all kinds of yarn. The warping process comprises of sturdy and well aligned CREEL of different capacities to accommodate the cones of varying diameters and weights as well as a winding headstock of different widths and flange diameters to wind the warp yarn on the dynamically balanced beam at high-speed with the help of unique “Spindle Driven Systems†coupled to powerful breaks. The Winding Headstock, which is the “Control Centre†of the warping systems, is available in three varieties, namely, hydraulic version, pneumatic version and the drum driven version. It is fully hydraulically operated AUTO version pre-assembled, synchronised and tested at the factory. The hydraulic system operates the press roll device, chucking and de-chucking device, doffing and donning of the beams.

It is also available in the pneumatic systems version, which is suitable for all varieties of yarn and has its advantages in lower cost for widths up to 1800 mm and flange diameter up to 800 mm. The shore hardness of the beam can be controlled by a unique system, which gives a very fine control in the hydraulic system to ensure uniformity of hardness through out the width with the help of the special press roll systems. The special press roll system is able to work with any kind of spun yarn and is available in a variety of coating like rubber, FRP and hard chrome plating thus ensuring a wound beam of desired hardness while keeping the press roll maintenance free for several years. Large capacity disk brakes are employed at all strategic locations of the machine like driving spindles, roller, etc, which gives powerful and efficient dynamic braking to the machine driven and for hardness controls. The sturdy construction of the machine ensures jerk free operation. The creel, which supports the cones, can be of 3 types:

- ‘V’ Creel with Revolving Frames

- ‘H’ (Parallel Creel with Revolving Frames

- Truck/Trolley on wheels parallel Creel.

Product & Technology News

- Beam widths: 1400 mm to 2400 mm

- Flange diameters: 800 mm, 1000 mm and 1400 mm

- Speeds: 600 mpm, 100 mpm or higher