Schedule a Call Back

Thermal Processing Services

Thermal Processing Services

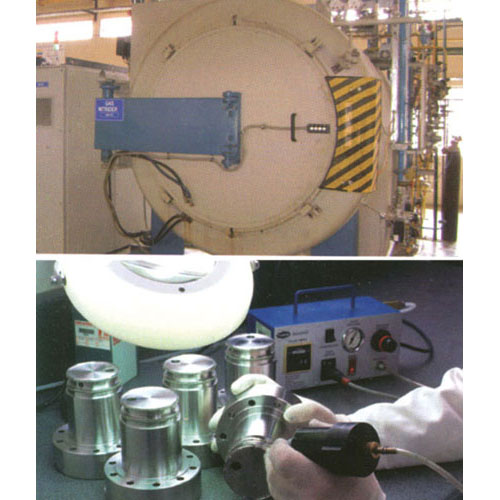

Bodycote, the world’s largest supplier of Thermal Processing Services, with over 180 plants worldwide, has launched a thermal processing plant at Pune that can provide a range of heat treatment processes. These include: Vacuum Processing – vacuum annealing, vacuum hardening and vacuum brazing (Al, Cu, Ag, Ni); Nitriding – plasma ion nitriding, gas nitriding and low pressure nitriding; Controlled Atmosphere Processes – ferritic nitrocarburising (FNC), FNC with post-oxidation, carburising, carbonitriding, nitrocarburising, hardening and tempering of stainless, hot die, cold work, high speed, and plastic mould and shock resistant steels; Air and Controlled Atmosphere – precipitation hardening, stress relieving and annealing; and Ancillary Services – sand/micro blasting, shot blasting, cryogenic treatment and specialists in plasma processing. Thermal processing is a vital part of any manufacturing process and includes a variety of techniques and specialist engineering processes, which improve the properties of metals and alloys and extend the life of components. The company also has an in-house laboratory at Pune for quality control and testing of material properties. It is a specialist provider of plasma nitriding services. Plasma nitriding is a low temperature treatment that provides full control of the composition and depth of the surface compound layer, thus preventing the spalling problems sometimes encountered with conventional nitriding and eliminating the need to lap critical surfaces after nitriding. Benefits of plasma nitriding: high hardness, strength and wear resistance; enhanced fatigue properties; no scaling or oxidation; very low distortion; no contamination, high degree of cleanliness; control of ‘white layer’; tailor-made phase mix (compound plus diffusion zone); and surface finish can be retained. Applicable materials: alloys and special steels such as HDS, HSS, D2 (HCHCr); tool steel, En 41B, En 19, En 24, OHNS; cast iron; aluminium, titanium and associated alloys; stainless steel (300/400 series) and heat resistant steel; and powder metallurgy components. The combination of vacuum hardening and plasma ion nitriding gives enhanced performance life for D2, HSS and HDS tools. Applications: automotive components; hot and cold forging dies; plastic injection moulding; valve components; hydraulic components; tooling components; glass industry dies and moulds; aluminium extrusion dies, etc.

Products from Bodycote Metallurgical Services India Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads