Schedule a Call Back

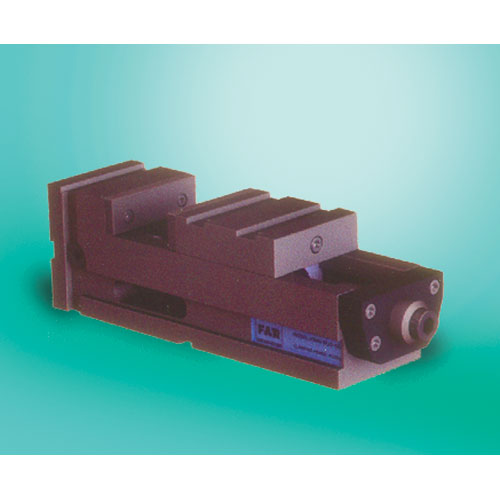

HYDRAULIC SELF-CENTERING STEADY REST

HYDRAULIC SELF-CENTERING STEADY REST

The FAR self-centering steady rests are compact and of advanced design enabling them to be used in restricted spaces. The user benefits are increased production on relatively long, thin or hollow components, reduced clamping time through rapid self-centering over the entire clamping range, and a high degree of centering accuracy and repeatability. Automatic clamping and unclamping by integrating with the machine controls can be used as a fixed or travelling steady. It can be mounted in any angular position. Repeatability of steady is 0.005 mm to 0.01 mm. The steady is available to hold components from 4 mm to 400 mm in diameter. Due to highly accurate self centering of these steadies, no undue pressure has to be applied from the tail-stock centre, which is a very important advantage in the machining of slender parts. Special steadies are available for machining of components of good tolerances by turning through space between rollers which is an additional advantage. The use of these steadies facilitates high cutting speeds and feeds to increase productivity. The marking and heating up of workpiece when using conventional steadies is totally eliminated by providing roller contacts. Wide opening angle of arms is advantageous for loading and positioning of components. Sealed housing prevents entry of chips and coolant. For heavy applications like machining of turbine shafts hydrostatic steadies are also available. Superir design and manufacturing methods linked with excellent quality control make the FAR products virtually trouble-free.The FAR self-centering steady rests are compact and of advanced design enabling them to be used in restricted spaces. The user benefits are increased production on relatively long, thin or hollow components, reduced clamping time through rapid self-centering over the entire clamping range, and a high degree of centering accuracy and repeatability. Automatic clamping and unclamping by integrating with the machine controls can be used as a fixed or travelling steady. It can be mounted in any angular position. Repeatability of steady is 0.005 mm to 0.01 mm. The steady is available to hold components from 4 mm to 400 mm in diameter. Due to highly accurate self centering of these steadies, no undue pressure has to be applied from the tail-stock centre, which is a very important advantage in the machining of slender parts. Special steadies are available for machining of components of good tolerances by turning through space between rollers which is an additional advantage. The use of these steadies facilitates high cutting speeds and feeds to increase productivity. The marking and heating up of workpiece when using conventional steadies is totally eliminated by providing roller contacts. Wide opening angle of arms is advantageous for loading and positioning of components. Sealed housing prevents entry of chips and coolant. For heavy applications like machining of turbine shafts hydrostatic steadies are also available. Superir design and manufacturing methods linked with excellent quality control make the FAR products virtually trouble-free.

Product & Technology News

Products from Fenwick And Ravi

SERVO Bar Feeders for Sliding Head Machines

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

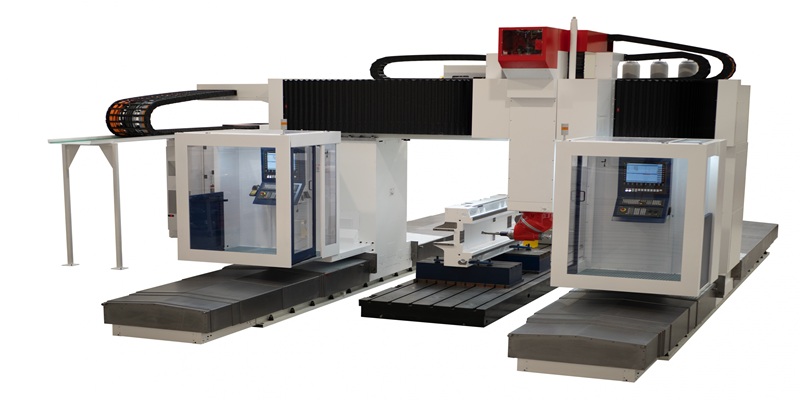

Versatile Machining Capability Through Ram Type Milling & Grinding Heads