Schedule a Call Back

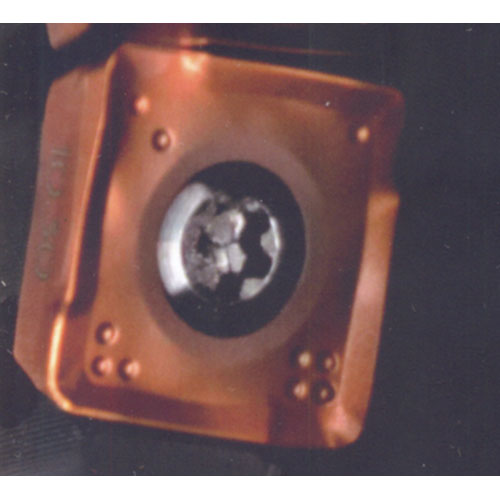

CoroMill 790 Al-cutter

CoroMill 790 Al-cutter

The inserts are firmly secured against the possible consequences of high radial forces generated at excessive speeds. This design also allows the tool to perform high ramping operations without feed reductions. The stiff cutter body is hardened before machining – a guarantee for maintained precision. To take best advantage, this tool is most effectively used for roughing to semi-finish ramping and circular interpolation in helix. It generates deep straight shoulders with practically no mismatch. Besides its capability for safe high speed machining, the cutter is also a power effective tool, capable of high metal removal rates per kW. It could also be used for many advanced high speed machining operations faced by die and mould makers, eg machining of deep cavities, steep ramping and circular interpolation in helix. A unique design of the support faces of the insert seats secures the inserts for possible consequences of the high radial forces generated at high speeds. The cutter body is hardened for optimised precision and together with the secured inserts this guarantees accurate location of the cutting edges. Together with the stable Coromant Capto coupling this new cutter gives high productive HSM performance for most demanding high-speed machining operations.

Product & Technology News

Products from Sandvik Asia Limited (Sandvik Coromant)

Tubes for Recuperator Applications

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads