Schedule a Call Back

CNC Plasma Cutting Machines

CNC Plasma Cutting Machines

Jana Precision Machines offers CNC Plasma Cutters. These are used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. Pierce and production cut 3/4" (19.05mm) mild steel*- maximum (1/2" or 12.7mm recommended)

Jana Precision Machines a technically advanced range of CNC Profile Cutting Machines, Mechanized Plasma Power Sources, Nesting Software etc. Our Plasma cutting machines are highly accurate providing excellent cutting quality and extended consumable life the other advantages being low investment and low operational cost and convenient for placing in a production line for automation.

Our plasma cutting machine can easily be operated and carried around the factory. It is produced adopting latest Plasma technology along with the state-of-the-art CNC Controls and Plasma power source etc. Advanced Plasma Technology provides high quality cutting finish on a wide range of material type and thicknesses

Standard System Components

- 3 pieces AC servo motor and drivers

- 3 pieces planet type gear box without gap

- 3 pieces incremental encoder

- Infinity CNC controllers

- Hi Focus 130 plus (plasma Generator )

- Auto nesting

- Automatic suction table and pneumatic system

Manual Plasma Cutting Equipment

Cutmaster 10mm The Cutmaster True 10mm manual plasma is an inverter based system specifically designed to provide excellent cutting and bevelling performance on materials up to 10mm thick. The unit is fitted with a state of the art power factor correction (PFC) module that provides maximum cutting capabilities from a 10 amp 240 Volt supply. Part Number: 1-4630-3

Cutmaster 20mm The Cutmaster True 20mm manual plasma system is designed to provide excellent cutting and bevelling performance on material up to 20mm thick. This inverter based design operates from a 415 Volt three phase supply and incorporates features such as auto-pilot re-start, True Guard roll bar and industry renowned SL60 1Torch for superior durability and consumable life. Part Number: 1-1130-3

Cutmaster 25mm The Cutmaster True 25mm manual plasma system is designed to provide excellent cutting and bevelling performance on material up to 25mm thick. This inverter based design operates from a 415 Volt three phase supply and incorporates features such as auto-pilot re-start, True Guard roll bar and industry renowned SL60 1Torch for superior durability and consumable life. Part Number: 1-1330-3

Cutmaster 35mm The Cutmaster True 35mm manual plasma is a high duty cycle, inverter based system specifically designed for heavy duty applications requiring superior cutting performance. The unit is specially designed to serve the 35mm market with a high duty cycle of 80% in a 40'C ambient environment. Part Number: 1-1730-3

Cutmaster 40mm The Cutmaster 40mm plasma is the largest air cooled manual system in the range. The heavy duty inverter system with a duty cycle of 80% in a 40'C ambient, is specifically designed for a high level applications requiring superior endurance and cutting performance Part Number: 1-1930-3

Thermal Dynamics offers two product families for air plasma cutting: Liquid cooled Auto-Cut systems for up to 300 amps of cutting power, and air-cooled CUTMASTER A-Series systems for light industrial applications.

THE CUTMASTER A-SERIES

The CUTMASTER A-Series family offers excellent cut quality in a lightweight, economical package. A-Series systems feature the 1Torch, Thermal Dynamics’ premium single-gas, air plasma torch.

Auto-Cut® systems feature a simple and robust gas control console. Like all Auto-Cut and Ultra-Cut®systems, they are equipped with Thermal Dynamics’ nitrogen/WMS cutting process for best in the industry cutting performance in aluminum and stainless steel applications.

High Precision Plasma Cutting System

Ultra-Cut® High Precision Plasma systems deliver high precision cutting performance on carbon steel AND on non-ferrous materials. For precision mild steel cut performance, select O2 plasma with Air shield. For precision aluminum or stainless steel, select N2 plasma with Water shield to achieve best in class cut performance. Ultra-Cut® systems can also be used for clean, efficient plasma marking without changing consumable parts.

Why choose Ultra-Cut ?

Ultra-Cut® high precision plasma has significant advantages over oxyfuel cutting in many applications.

- upto 3 Times faster than oxy-fuel torches

- Pierces 35 mm(1 1/4") in 1 second

- 1 Ultra Cut 400 can replace 4 Oxy-Fuel torches, each requiring its own torch height controller

- Ultracut Cuts Aluminium and stainless steel with excellent cut quality

- No pre-heat

(In all our Plasma Cutting Machines we incorporate Thermal Dynamics products for which we seek help of our associate company who is the Indian channel partner of Thermal Dynamics, U.S.A.)

Controllers Features:

- Automatic referencing

- Starting Point designation

- Auto Nesting

- On Board Nesting

- Plate leveling

- Microsoft Windows XP

- Software PLC screen 512Kb

- Reading of *.dxf and *.Dwg files and converting machine language by linatrol Cut Software

Products from Jana Precision Machines

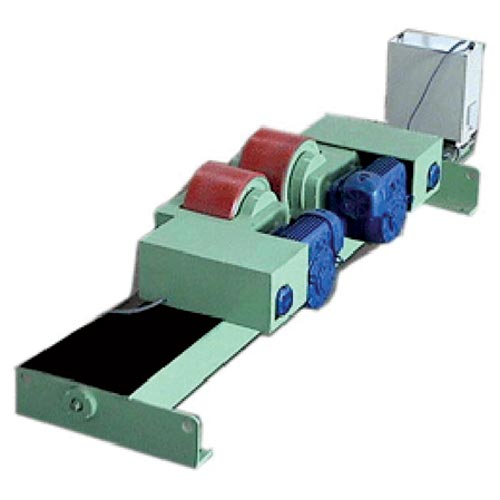

Welding Rotators, Self-Aligning

Rebuilds, CNC Retrofits, Machine Tools

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads