Schedule a Call Back

Hot Forging Cost Reduction

Hot Forging Cost Reduction

Hot forging involves plastic forming of heated metals and alloys into desired shapes. In a forge shop, die cost amounts to 10% to 15% of the forging cost. Any increase in the die life automatically increases the profitability of the forge shop. Lubricants play three important roles: 1. Reduction in forging load; 2. Improvement in metal flow; and 3. Prevention of sticking of forged material to the die, thereby increasing the die life. Furnace oil, which is used as a ‘lubricant’ in many forge shops does not give the expected results. From the pollution point, its use should be avoided. An Indian firm has studied the needs of the forging industry in depth and come out with a range of die lubricants. ESPON-LSS is a breakthrough in hot forging. It increases die life by 30% to as high as 80%. The striking features of ESPON-LSS are water miscibility, smokeless atmosphere, non-hazardous nature, economy in use and distinct improvement in the surface finish of the forgings. The same firm has developed special lubricants for hot forging of stainless steel (ESPON-DLO/V), brass (ESPON-ELB), ESPON-HF anti-scale compound prevents scale loss and decarburisation during heating for hot forging. All these products are found useful by a large number of forge shops in India.

Product & Technology News

Products from Steel Plant Specialities LLP

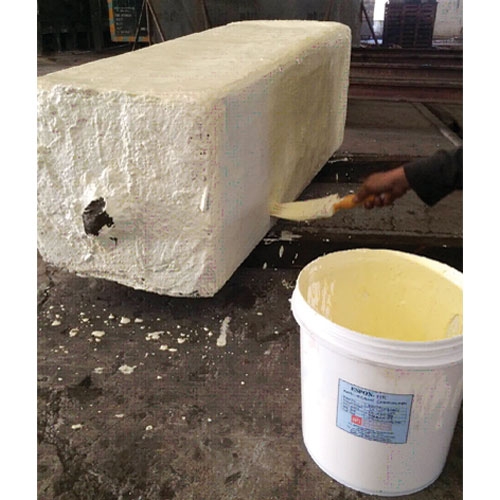

Anti Scale Coating Compound For Hot Forging

Refractory Coating For Furnaces

Accurate Proportioner For Correct Mixing Of Coolants And Lubricants

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads