Schedule a Call Back

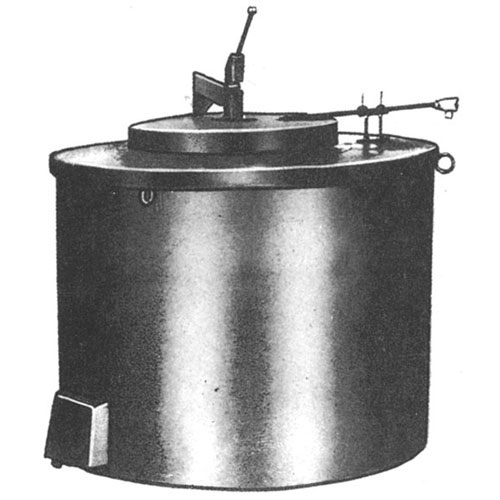

Heating & Pumping Unit

Heating & Pumping Unit

Technotherm Engineers offers pre-packaged fuel oil Pumping and Heating Units. These are standard, pre-engineered, "custom designed" systems utilising standard components. They are tailored to provide efficient dependable delivery to heavy viscosity fuel oils to furnaces, kilns, ovens, dryers, boilers, etc., at pressure of 15-20 psi and temperature of 90-100°C, near burner tip. All the components are pre-sized and selected for optimum performance when interfaced with each other. The company’s fuel oil handling system minimises start-up and operating difficulties and reduces maintenance costs. Each unit is shipped completely assembled on a skid and interconnected with, properly sized pipings, fittings and required hardware. It is ready for connection to the on-site fuel supply and electrical power. A normal TEPL pumping and heating unit includes basket filters (cold and hot oil side), direct couple motorised gear pump, pressure regulating and pressure relief valves, pressure gauge, electrically heated oil pre-heater thermostatically controlled with the temperature indicator. The system is available in following models: Simplex (single gear pump with motor and single heater); Duplex-I (two gear pumps with motor in parallel and single heater); and Duplex-II (two gear pumps with motor and two sets of electric heaters, all in parallel). Features: pre-engineering to exact requirements, skid mounted and pre-pied, easy field installations, guess work eliminated, built in thermostat for automatic control of oil temperature. Heating and pumping unit: when high viscosity of oil is to be fired, it is advisable to preheat oil between 90 to 100°C. This temperature is applicable for furnace oil and LSHS, also for better combustion it is necessary to provide a pressure of 15-20 psi at burner tip. Built in thermostat will ensure automatic control of oil temperature. While selecting the requirements, consider 1 kW of heater can preheat 10 litres per hour of furnace oil from 25 to 100°C. In the event of pipe length too long, consider 1 kW for every extra length of 10 mtr. The recommended pump capacity will be higher by 150 to 300% of oil consumption in burner, balance quantities circulate in ring main system.

Product & Technology News

Products from Technotherm Engineers Private Limited

Bale Out Furnace, High Efficiency

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads