Schedule a Call Back

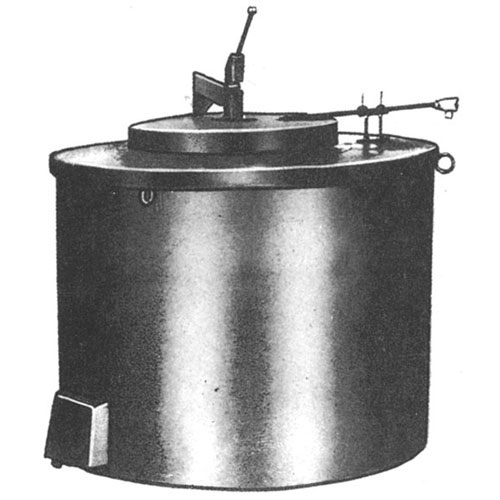

Bale Out Furnace, High Efficiency

Bale Out Furnace, High Efficiency

Technotherm Engineers has introduced an oil/gas fired Bale Out Furnace duly lined with ceramic fibre lining along with highly efficient monoblock type burner. With the use of this burner in place of conventional burner, the main advantages are hereunder: reduction in electricity consumption more than 90%, reduction in oil consumption about 30%, reduction in initial/subsequent heating time, auto control On/Off or modulating type, and accuracy in temperature control by digital controller. Some of the areas in which improvement can be made with a view to conserve energy and reduce the operating cost are discussed in brief as under: low thermal mass lining – a new type of refractory/insulation material namely “Ceramic Fibre†has been introduced recently in the above furnace. This product has a low thermal mass and thus a unique advantage of very low heat storage. With the use of this material in place of conventional refractory, initial heating time of the furnace is considerably reduced resulting in substantial fuel economy and increased furnace availability. In addition its use, (because of its low thermal conductivity) bring down the skin temperature of the furnace, thus reducing the radiation losses considerably. Fuel efficient monoblock type burner – the furnace will be provided burner based on pressurised combustion technology, which work on very low excess air. By excess air is meant, the quantity of air needed over and above that theoretically required for complete combustion. The excess air, which does not take part in combustion, un-avoidably takes away heat from the furnace and increases the stake losses, resulting in poor combustion efficiency. Due to lower excess air in the burner, the efficiency of burner is more than 90%. These burners are having following features: in-built blower, in-built pump, sequence controller, flame failure sensor (PEC), electrodes for auto-ignition, and solenoid valve/modulating motor for automatic fuel control.