Schedule a Call Back

Waste Heat Recovery from Furnaces/Kilns

Waste Heat Recovery from Furnaces/Kilns

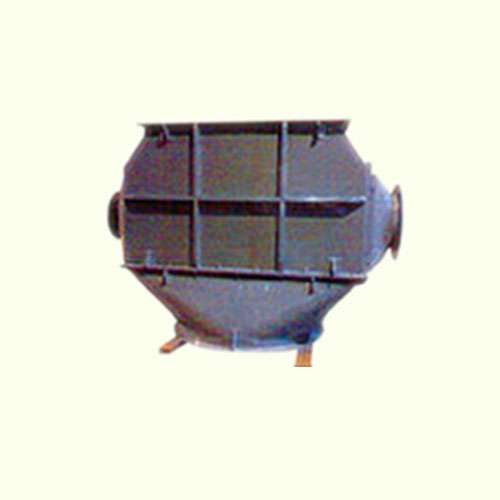

In any industrial furnace, the exhaust gases leave at high temperature from the chimney. Sensible heat losses in the exhaust gases, while leaving the chimney, carry 20% to 50% of the heat input to the furnace. If this heat could be recovered and reused, there would be saving in fuel consumption and time. The higher the quantum of excess air and exhaust gas temperature, the higher would be the waste heat availability. The waste heat can be partly recovered by pre-heating the combustion air by the outgoing exhaust gases. This is done in equipment called Recuperator or air pre-heater. For this purpose, Jodhpur-based Hindustan Radiators and Heat Exchangers designs and manufactures such recuperators. These recuperators are designed and manufactured for individual furnaces used in the industry. However, a saving of about 10% or more in fuel is generally achievable. The use of pre-heated air increases the temperature in furnace, reducing the process time and improving the quality of the product. The time required for bringing the furnace to heat (charging time or initial heating time) is reduced about 20% to 30%. There is reduction in scale losses. Pay back period on investment is generally 8 to 12 months. The recuperator can be installed in the exhaust gas passage as part of the chimney.

Product & Technology News

- The fuel consumption is reduced

- The rate of reduction depends on the temperature of the fuel gases, the percentage excess air used, and the temperature to which the air is preheated

Products from Hindustan Radiators And Heat Exchangers Private Limited

Air Coolers for Motors & Generators

Air Coolers For Large Electric Motors & Generators

Charging Air Coolers (After Coolers) For Diesel Engines

Fire & Rodent Protective Cable Coating

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads