Schedule a Call Back

Continuous Conveyor Hardening & Tempering Plants

Continuous Conveyor Hardening & Tempering Plants

Fluidtherm Technology Pvt Ltd designs Continuous Conveyor Hardening and Tempering Plants for process capabilities like: neutral hardening and tempering, carbonitriding, shallow case carburising, austempering, and carbon restoration and hardening. Consistency of quality is better obtained when components are continuously quenched, a few pieces at a time instead of in a batch at periodic intervals. Of the total tonnage of heat treated components the majority do not require fixturing and can tumble into a quench tank. The ideal plant for all such components in terms of quality, capital cost as well as operating cost is a continuous conveyorised heating and quenching system. Components spend less time at temperature and consume less energy compared to batch furnaces. Continuous quenching, a few components at a time, ensures a high degree of quality consistency in terms of hardness, case depth and physical properties. Such plants with conveyorised auxiliary equipment for loading, washing and tempering are normally fully automated.

Typical components processed:

- Bearing parts, chain parts, fasteners, springs, circlips, needles, appliance parts, auto parts, lock parts, hand tools, shoe shanks

- Hardening and tempering chain parts, screws, appliance parts, auto parts, PM parts, bicycle parts, bearing parts

- Carbonitriding/shallow case carburising

- Loading by soft handling, weigh feed, metered loading, vibratory conveyor, etc

- Wash machines – high intensity jet spray, dunk and spray, steam wash, ultra sonic, vapour degreasing and in line centrifuge, drying, continuous dirt filtration, oil separation/recovery, salt recovery

- Suitable furnaces and heaters

- Quenching – oil, hot oil or polymer, clog resistant cascade curtain, variable agitation, continuous dirt removal, air/water heat exchangers, air knife, electric heaters or gas tube burners, temperature, level and flow controls

- High convection (high uniformity) tempering, rapid heat up feature, jet heating system, nitrogen atmosphere capability, steam tempering facility, post temper blackening tank

- Suitable controls, unloading, etc.

Products from Fluidtherm Technology Private Limited

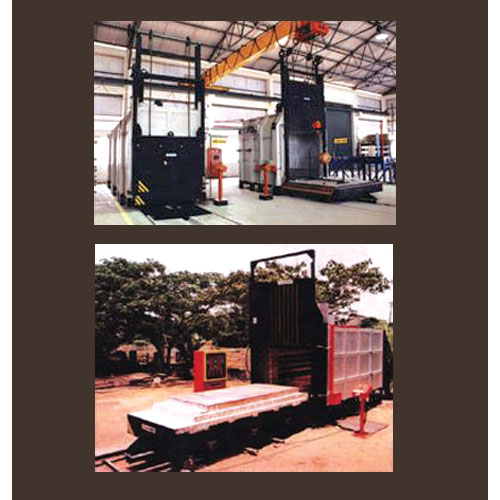

Car Bottom Furnaces/Bogie Hearth Furnaces

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads