Schedule a Call Back

Gear Production, Workholding & Inspection Solutions

Gear Production, Workholding & Inspection Solutions

Gleason, the Total Gear Solutions Provider, is introducing advanced machines, tooling, and global customer support services covering a wide array of processes for the complete production and inspection of all types of bevel and cylindrical gears at Gear Expo 2015 (October 20-22 at the Cobo Center in Detroit, Michigan).

The Genesis® 200GX Threaded Wheel Grinding Machine is an innovative platform for automotive gearbox parts and more. The 200GX is the latest addition to the highly popular Genesis® series and offers many features. The two spindle concept combines maximum productivity with minimised idle and set up times. Fast, easy software-guided set-up of the machine allows users to set up the machine from one workpiece to another in just 20 minutes using only one tool. "First Part Cycle" – fully automatic workflow after set-up until grinding the first workpieces and the ability to interface with Gleason GMS® machines via QR codes increase productivity. Easily accessible machine components make maintenance simple and efficient while standard dimension grinding wheels and dressing tools allow use of existing tools. All of this in an energy efficient small footprint machine designed to meet the needs of customers in high-productivity high-quality environments.

The Gleason 300GMS®P Analytical Gear Inspection System is designed to operate in production environments while yielding reliable measurement results. A unique patent-pending base design includes an active levelling system to attenuate a broad spectrum of normal production environment vibrations, yielding measurement values in parallel with those achieved in controlled calibration laboratories, but without the delay of having to move to the lab location. Thermal fluctuations normally associated with shop floor environments are proactively compensated for as well, allowing for the best possible and most reliable inspection results. The system identifies and applies a compensation for factory floor influences in real time.

The 300GMS®P Analytical Gear Inspection System is designed and tested to perform as a turn-key gear inspection system in the manufacturing environment, and is the solution to reliable, accurate, gear inspection for today’s demanding applications in aerospace, automotive, and smaller power transmission industries.

Other significant products, technologies and services, include:

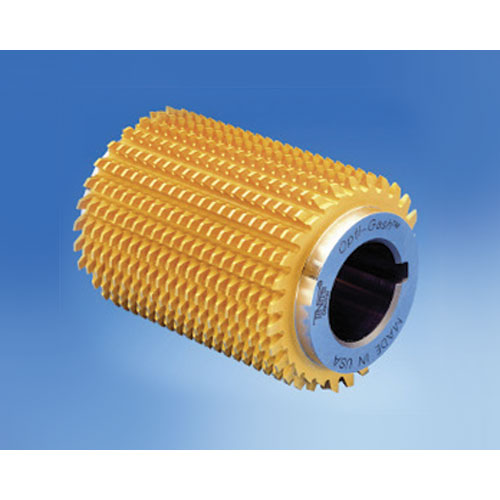

- Most complete line of gear cutting tool solutions – virtually every cutting tool type for the production of cylindrical and bevel gears of all types and sizes. For cylindrical gear production, a full array of hobs, form relieved milling cutters, solid carbide hobs, shaper cutters, chamfering and deburring tools, shaving cutters, honing tools, coated diamond and CBN grinding wheels, diamond dressing wheels and diamond dressing rolls; G90 tooling material, which closes the performance gap between HSS materials and tungsten carbide; and an assortment of Power Skiving tools as the total source for supporting this process.

- Bevel cutting tool display featuring advanced new bevel gear cutting tools for cutting and grinding straight, spiral and hypoid bevel gears. Of particular note is the Pentac®Plus – RT which can be built faster and more precisely than stick blade cutter systems of the past. With blade seating stiffness equal to the high stiffness of Pentac Plus, this new system offers superior surface finish, tool life and cycle time.

- Advanced workholding solutions – complete range of quick-change, tool-less workholding equipment for bevel gear, cylindrical gear and non-Gleason production machines. These systems significantly reduce set-up and changeover times for gearing applications up to 600 mm in diameter. Quik-Flex® Plus, Gleason’s next generation of modular, quick-change workholding systems which requires a single tool, less time and minimal operator experience will be on display for the first time at Gear Expo. Also on display will be a line of hydraulic workholding solutions.

- Gleason Global Services – factory trained service professionals located throughout the Americas, Europe, and Asia, working around the clock to deliver the full range of aftermarket service and support capabilities including service programs for preventive maintenance, machine inspection, troubleshooting and repair and machine relocations. Complete range of machine rebuilding and re-controls now offered for all types of Gleason machines. The company is also the leading source of education for gear technology.

- Gleason Plastic Gears – plastic gear design and injection moulded plastic gears including helical gears, spur gears, planetary gears, internal gears. Distech Systems – specializing in the design and manufacture of factory automation systems serving a variety of customers in the automotive and other industries. Combining customised automation technology with Gleason products for gear (and non-gear) production.

Product & Technology News

Products from Gleason Works Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads