Schedule a Call Back

Industrial Process Control

Industrial Process Control

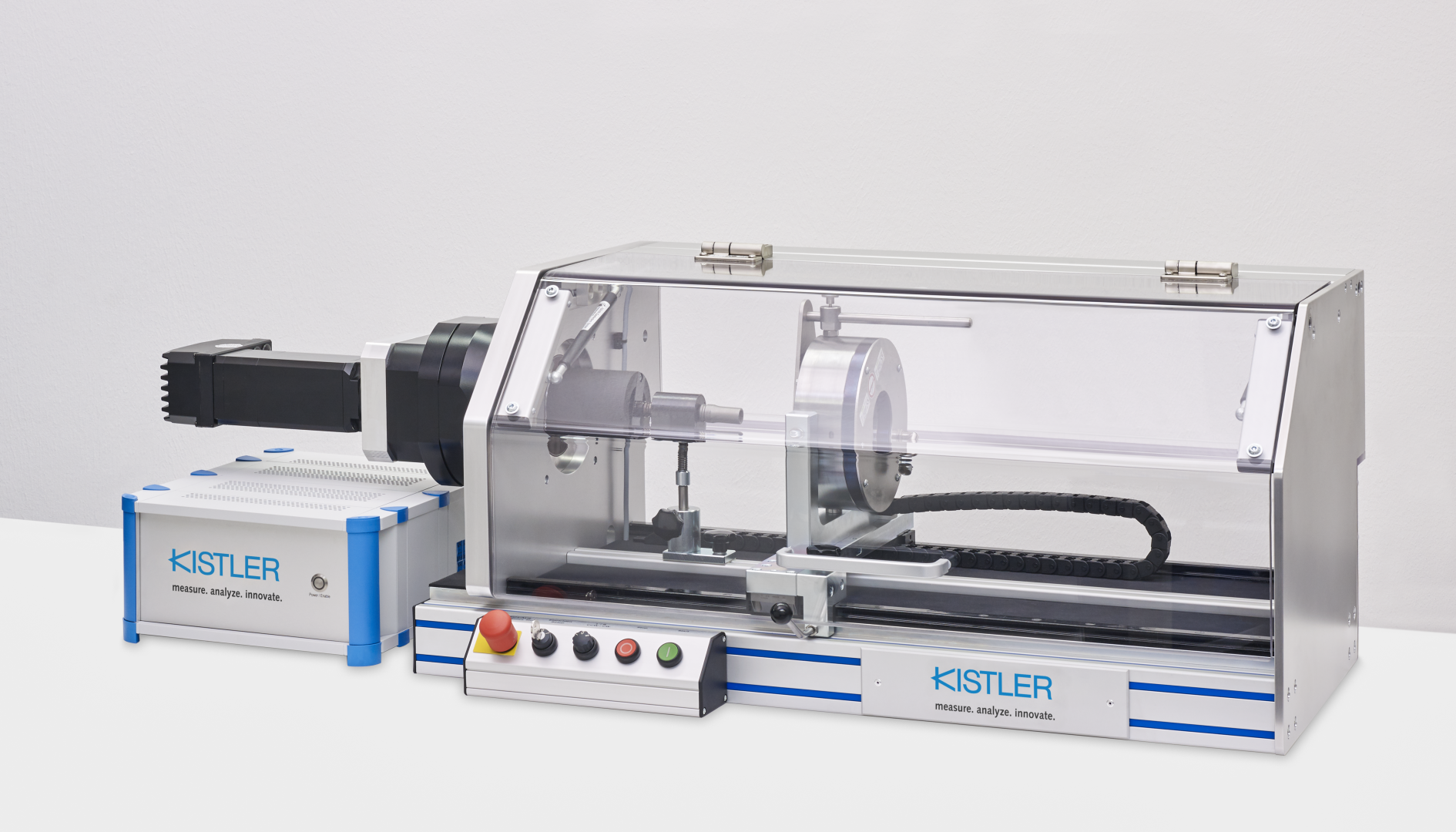

In virtually every sector of industry, assembly with bolts and screws is one of the most frequently used joining processes in manufacturing. That's why it's crucially important for bolted joints to function safely and reliably – otherwise, there will be the risk of recalls and additional costs. To maximize quality and cut costs, fastening technology must be continuously monitored and tested. And to achieve this, Kistler offers an extensive portfolio of test and analysis systems. They analyze the functional characteristics of bolted joints (such as the coefficient of friction, preloading force or torque) and also bolting tools; they capture all the measured values and provide a clear presentation of the documented results. These systems allow targeted monitoring of tolerance limits, and they ensure that process deviations in fastening technology are detected at an early stage.

Product & Technology News

Thanks to our high-performance hardware and software, measurements of torque and rotation angles are simple, fast and efficient. Calibration of torque tools is essential in any modern production facility – but certification is also an absolute requirement. High-performance tools play an important part in producing reliable bolted joints, but inspection and verification of the fastener components and the bolted joint are also key factors. Kistler offers an extensive range of products for quality assurance in the bolting process. Piezoelectric reaction torque sensors deliver precise torque measurements so that handheld screwdrivers can be reliably calibrated

In virtually every sector of industry, assembly with bolts and screws is one of the most frequently used joining processes in manufacturing. That's why it's crucially important for bolted joints to function safely and reliably – otherwise, there will be the risk of recalls and additional costs. To maximize quality and cut costs, fastening technology must be continuously monitored and tested. And to achieve this, Kistler offers an extensive portfolio of test and analysis systems. They analyze the functional characteristics of bolted joints (such as the coefficient of friction, preloading force or torque) and also bolting tools; they capture all the measured values and provide a clear presentation of the documented results. These systems allow targeted monitoring of tolerance limits, and they ensure that process deviations in fastening technology are detected at an early stage.

Thanks to our high-performance hardware and software, measurements of torque and rotation angles are simple, fast and efficient. Calibration of torque tools is essential in any modern production facility – but certification is also an absolute requirement. High-performance tools play an important part in producing reliable bolted joints, but inspection and verification of the fastener components and the bolted joint are also key factors. Kistler offers an extensive range of products for quality assurance in the bolting process. Piezoelectric reaction torque sensors deliver precise torque measurements so that handheld screwdrivers can be reliably calibrated.