Schedule a Call Back

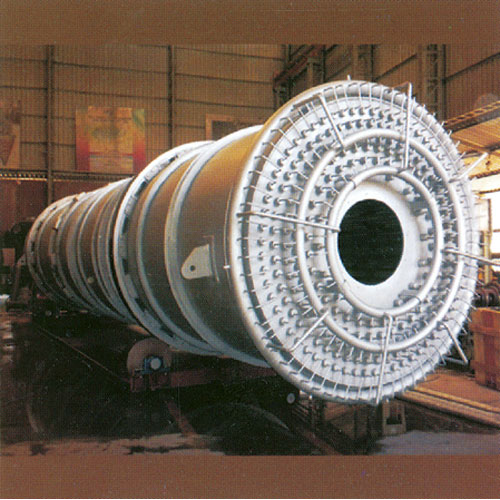

Steam Tube Bundle Dryer

Steam Tube Bundle Dryer

Raj Process Equipments & Systems offers a Steam Tube Bundle Dryer, based on the conduction mode for drying. The product to be heated and dried only contacts steam heated tubes, and not directly the steam. Tube bundles are operated on the counter-flow principle, (i.e., steam flows in the direction opposite to the direction of the material flow). The tube bundle dryers are designed by considering the wet and dry product flow characteristics, lump crust formation tendency and thermal sensitivity of the material in dry condition. Indirect steam tube rotary dryer: the tubes are arranged in a circumferential manner on the inner periphery of the rotating shell. This entire shell and tubes assembly is supported on tyres/rollers and driven through suitable gear drive. Wet feed material is fed through material inlet nozzle installed at one end of the shell of dryer. This wet feed is fed through screw feeder. Feed material showered on the tubes with the help of lifting blades which are mounted on the rotating shell. Steam enters in the tubes through rotating joint installed at material discharge end of the shell. Material gets dried and discharged from the material discharge ports on the shell. Vapours are removed from the feed end with the help of suction blower after separating fines in the cyclone separator. The suitable sealing arrangement is provided to prevent air leakage and product losses. Rotary tube bundle dryers: the tube bundle is rotated inside the stationary insulated housing. Steam is passed though one end of tube bundle for drying and condensate is removed from the other end. Wet feed material to be dried is fed into the stationary dryer housing from feed nozzle at one end. The material gets lifted up and showered on tubes with the help of lifting blades provided on tube bundle periphery. Material gets dried by conduction heat transfer and it is discharged from the other end.